Solenoid valves play a crucial role in controlling fluid and gas flow across countless industrial and commercial applications. From manufacturing plants to HVAC systems, these devices offer precise operation with minimal human intervention. Among the technical considerations that affect performance, coil polarity often raises questions for engineers, maintenance teams, and facility managers. Understanding how coil polarity impacts a solenoid valve can help prevent operational issues, extend component life, and improve overall system efficiency.

The Basics of Solenoid Valve Operation

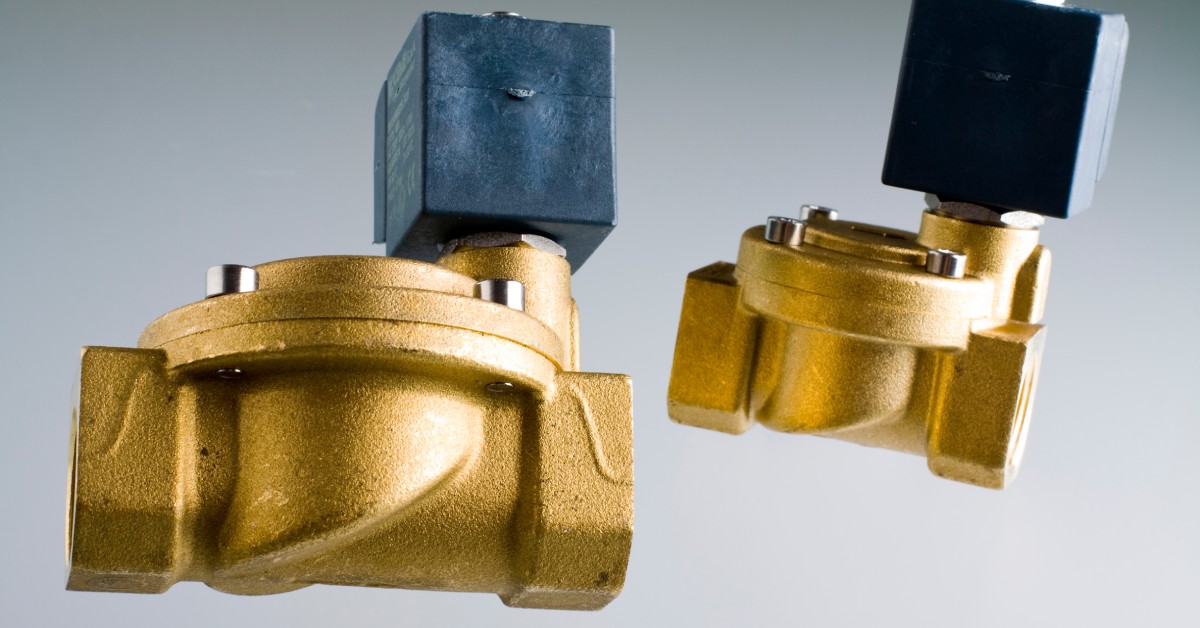

A solenoid valve consists of a coil of wire, a movable plunger, and a valve body that opens or closes in response to electrical signals. When current passes through the coil, it generates a magnetic field that moves the plunger, which in turn controls the flow of a liquid or gas. The speed, accuracy, and reliability of this movement depend on multiple factors, including voltage, current, and, importantly, coil polarity.

Most solenoid valves operate on either direct current (DC) or alternating current (AC). DC valves require consistent polarity because reversing the current can affect the magnetic field and alter the plunger’s motion. AC valves, on the other hand, are less sensitive to polarity due to the alternating nature of the current, but they still rely on correct wiring for safe and efficient operation.

Why Coil Polarity Matters

Correct coil polarity matters because it directly influences the solenoid’s magnetic field. Reversing polarity in a DC solenoid can change the direction of the magnetic flux, which may cause slower response times or incomplete plunger movement. In some designs, reversing polarity can even lead to coil overheating or permanent damage to the insulation.

Polarity also affects system reliability. A solenoid valve that operates intermittently due to incorrect wiring can lead to downstream process interruptions, product waste, or safety hazards. Operators and maintenance teams need to understand which terminals are positive and negative and how these designations interact with the broader electrical system.

Identifying Coil Polarity

Manufacturers typically label solenoid valve coils to indicate positive and negative connections. Common markings include plus and minus symbols, colored wires, or terminal engravings. Reading these labels correctly prevents wiring mistakes during installation or maintenance.

For DC solenoids, connecting the coil with the correct polarity aligns the magnetic field with the mechanical plunger movement, resulting in full travel and optimal performance. Reversing the connections may still allow the solenoid to function, but with reduced efficiency, slower response, and higher energy consumption. AC solenoids do not require a specific polarity, but they still need proper voltage matching and correct terminal connections to avoid short circuits or other electrical issues.

How Polarity Affects Performance

The effect of coil polarity becomes more pronounced under certain operating conditions. For example, in applications requiring rapid cycling, even a minor delay in plunger movement can compromise flow control. Incorrect polarity can cause the plunger to hesitate or fail to seat fully, which reduces system accuracy.

Voltage fluctuations also interact with polarity issues. A correctly polarized DC solenoid operates efficiently across its rated voltage range. When polarity reverses, the coil may draw excessive current to achieve the same magnetic force, potentially leading to overheating or premature failure. In addition, switching transients, such as spikes from a motor or power supply, can exacerbate polarity-related stress on the coil and surrounding circuitry.

Solenoid Design Considerations

Solenoid design incorporates polarity considerations to optimize performance and durability. Engineers select wire gauge, coil turns, and plunger materials to produce a specific magnetic field strength under rated voltage. Many modern designs include protection features such as diodes or varistors to handle polarity errors or voltage spikes.

Diodes in DC solenoids, for instance, prevent current from flowing in the wrong direction and protect against back EMF generated when the plunger moves. This type of protection allows solenoids to tolerate brief polarity reversals during troubleshooting or temporary wiring errors. However, consistent miswiring still places stress on the coil and reduces its service life.

Solenoid design also affects thermal performance. Coils generate heat during operation, and incorrect polarity can increase electrical resistance or cause uneven magnetic fields, concentrating heat in certain areas. A robust design addresses these risks through insulation, heat-resistant materials, and optimized coil geometry, all of which help the solenoid withstand demanding operational conditions.

Installation and Maintenance Best Practices

Proper installation directly impacts how solenoid valves respond to polarity considerations. Technicians must verify voltage type, terminal markings, and wiring orientation before energizing the system. A multimeter can confirm continuity and polarity in DC circuits, providing an extra layer of safety.

During maintenance, teams should inspect connections for corrosion, loosened screws, or damaged insulation. Even high-quality solenoid valves suffer performance degradation if wiring connections introduce resistance or intermittent contact. Cleaning terminals and tightening fasteners helps maintain consistent coil performance and prevents polarity-related issues from developing over time.

Routine testing also supports reliable operation. Activating the solenoid under controlled conditions allows operators to observe plunger movement and identify any delays or misalignment. These checks reveal whether coil polarity or electrical supply issues are affecting performance before the valve enters critical service.

Safety Implications

Incorrect coil polarity can pose safety risks in certain applications. For example, solenoid valves in fluid handling systems may control chemicals, compressed air, or high-pressure water. A valve that fails to actuate fully can cause spills, pressure buildup, or system overpressure. Confirming correct polarity reduces the likelihood of these incidents and keeps operational environments safe for personnel and equipment.

Electrical safety also comes into play. DC coils that operate with reversed polarity may heat excessively, creating a potential fire hazard or damaging nearby components. Following proper wiring protocols and verifying polarity protects both the solenoid and the surrounding system infrastructure.

Troubleshooting Polarity Issues

Signs of polarity-related problems include slow plunger response, incomplete valve seating, unusual heat generation, and erratic operation. When technicians observe these symptoms, checking the coil wiring should be a priority.

Reversing connections on a DC solenoid often corrects sluggish operation and restores full movement. For systems that cycle frequently, confirming consistent polarity across all solenoids prevents cumulative wear and reduces maintenance downtime. In AC systems, issues are more likely related to voltage mismatch, short circuits, or other wiring errors rather than polarity itself.

Choosing the Right Solenoid Valve

Selecting a solenoid valve involves matching the device to the application’s electrical and mechanical requirements. When specifying DC valves, polarity sensitivity should influence component selection. Valves with built-in protective features like diodes offer additional resilience, especially in complex systems with multiple solenoids.

Voltage rating, response time, and flow capacity all intersect with polarity considerations. A high-speed solenoid may require precise wiring to operate correctly, while larger valves with heavier plungers might tolerate minor polarity errors without immediate performance loss. Understanding these interactions helps engineers choose valves that meet operational goals while reducing the risk of miswiring or system downtime.

Long-Term Performance and Reliability

Consistent attention to coil polarity contributes to long-term reliability. DC solenoids that operate with correct polarity experience lower electrical stress, uniform heating, and predictable magnetic performance. This reduces wear on the coil, plunger, and valve body, extending the service life of the entire assembly.

Preventive maintenance practices, such as periodic testing, terminal inspection, and cleaning, reinforce the benefits of proper polarity. By proactively addressing wiring issues and confirming correct electrical connections, facility managers and maintenance teams can maintain high system uptime and avoid costly replacements.

Understanding solenoid valve coil polarity is essential for reliable operation, safety, and longevity. Correct polarity in DC solenoids maximizes magnetic efficiency, supports consistent plunger movement, and prevents overheating or damage. AC solenoids are less sensitive but still require accurate wiring and voltage matching.

Incorporating polarity considerations into installation, maintenance, and system design helps maintain smooth operation and reduces operational risk. Choosing solenoids with protective features, following manufacturer labeling, and testing connections periodically all contribute to reliable performance. Proper solenoid design also accounts for polarity, optimizing coil geometry, insulation, and thermal management to handle operational demands.

By paying attention to coil polarity, engineers, technicians, and facility managers can achieve precise control, improved system efficiency, and longer-lasting components. Solenoid valves may be small, but understanding their electrical characteristics has a significant impact on the performance and safety of the systems they control.