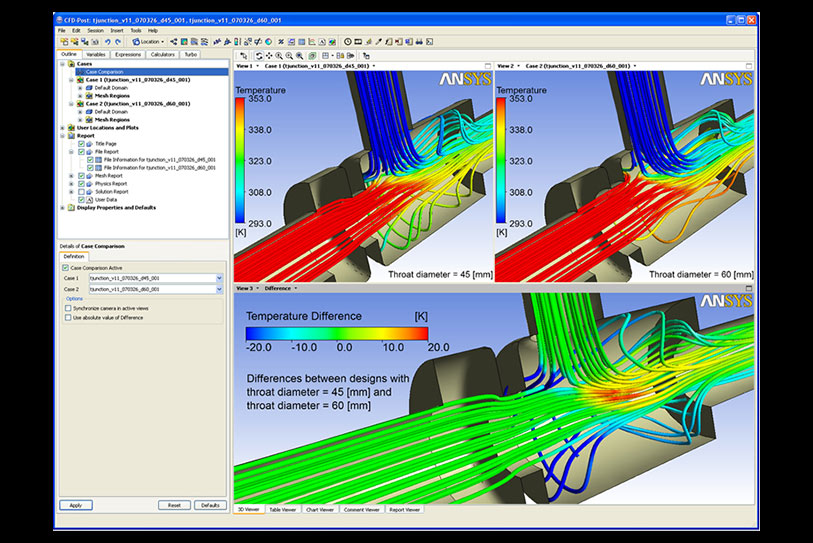

Computational Fluid Dynamics (CFD) Analysis

Solenoid Systems uses ANSYS CFD analysis tools to design optimized solutions and create virtual products that solve complex fluid dynamics problems for solenoid valves used in hydraulic and pneumatic systems. Our innovative solution analyzes:

- Laminar and turbulent flows

- Incompressible and compressible fluids

- Multiphase flows, and more

Solve Complex Fluid Dynamics Problems

Fluid dynamics problems have become more complex as product designs and processes grow in sophistication and companies tighten product development schedules, requiring engineers to analyze problems quickly with a high degree of accuracy.

Our accurate and efficient analysis capabilities afford engineers time to explore design alternatives, build in product innovation and optimize solenoid systems and valve operation within our customers’ aggressive product development schedules.

Computational Fluid Dynamics Analysis allows us to examine every aspect of fluid behavior under various conditions. This detailed examination provides precise insights that enable us to tailor solenoid system designs to meet specific client needs. The analysis ensures rapid problem-solving and iterative design improvements, significantly reducing product development costs for our clients.

Multi-Faceted Analysis

Solenoid Systems can couple Computerized Fluid Dynamic Analysis and problem solving with other Finite Element Analysis tools, such as Electromagnetic Mechanical and Thermal Analysis to provide a Multi Physics solution that accounts for external physical forces.

By integrating CFD Analysis with these tools, we can simulate real-world conditions, ensuring our solutions perform optimally in any scenario.

Consulting Services and Project Assessments

Solenoid Systems can provide design input, technical expertise, and gauges efficiency for optimal performance. The ability to couple electronic circuits and external loads to the electromagnetic analysis lets our engineers simulate the solenoid in its application. This allows us to create and validate a virtual prototype that meets customer specifications. Once we have a virtual prototype, we can manufacture a physical prototype with a high confidence of success to eliminate costly iterations.

By leveraging Computational Fluid Dynamics Analysis, we enhance solenoid and valve operation, leading to better system performance, reliability, and durability. These benefits directly impact our clients’ end products and customer satisfaction.

Overall, our accurate and efficient analysis capabilities allow us to manage strict product development schedules. Therefore, we can ensure high accuracy and performance optimization within tight timeframes.