Solenoid valves are among the most versatile and widely used flow control devices across countless industrial applications. These electromechanical components control the flow of liquids, gases, and other media through automated switching mechanisms. Engineers and technicians rely on solenoid valves to achieve precise control of fluid systems, making them indispensable in manufacturing processes, automotive systems, and countless other applications that require automated fluid control.

Modern industrial applications demand reliable, efficient, and precisely controlled fluid management solutions. Solenoid valves meet these requirements through their robust construction, rapid response times, and seamless integration with automated control systems. The versatility of these devices extends across numerous industries, from simple on-off applications to sophisticated proportional control systems that regulate flow rates with exceptional accuracy. Continue reading to begin to understand the components of a solenoid valve.

Key Components

Solenoid Coil

The solenoid coil serves as the electromagnetic heart of the valve, converting electrical energy into the magnetic force that powers mechanical operation. This component consists of copper wire wound around a bobbin, creating an electromagnet when energized. The coil generates a magnetic field that attracts or repels internal metallic components, producing the linear motion necessary for valve actuation. Different coil configurations accommodate various voltage requirements, power consumptions, and response characteristics depending on specific application demands.

Valve Body

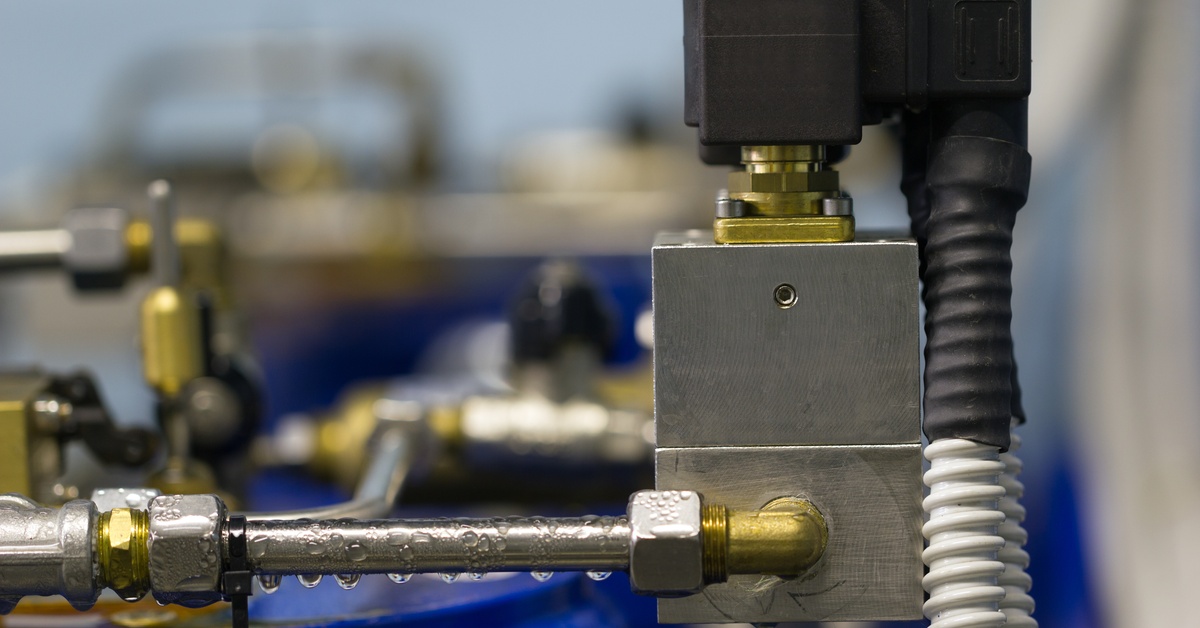

The valve body houses all internal components and provides the structural foundation for media containment and flow direction. Engineers design valve bodies to withstand specific pressure ratings, temperature ranges, and chemical compatibility requirements. The body incorporates precisely machined passages that direct media flow through predetermined pathways while maintaining leak-tight seals. Port configurations, threading standards, and mounting provisions integrate into the body design to facilitate system installation and maintenance procedures.

Plunger or Poppet

The plunger or poppet serves as the primary moving element that physically opens or closes the flow pathway. This component responds directly to magnetic forces generated by the solenoid coil, translating electromagnetic energy into mechanical valve operation. The plunger design incorporates sealing surfaces that mate with corresponding valve seats to achieve leak-tight closure when de-energized. Spring mechanisms typically provide a return force to maintain specific valve positions when electrical power leaves the coil.

Orifice

The orifice defines the flow-path dimensions and directly influences the valve’s flow-capacity characteristics. Engineers calculate orifice sizing based on required flow rates, pressure differentials, and media properties to optimize system performance. The orifice geometry affects the pressure drop across the valve, the flow velocity, and the potential for cavitation in liquid applications. Precision machining of orifice dimensions maintains consistent flow characteristics and prevents performance degradation over extended operating periods.

How a Solenoid Valve Works

The operational sequence begins when electrical current flows through the solenoid coil, creating an electromagnetic field around the coil assembly. This magnetic field generates attractive or repulsive forces that act upon the ferromagnetic plunger or poppet within the valve assembly. The magnitude of the magnetic force depends on coil design parameters, applied voltage, and the magnetic permeability of the plunger material.

As the magnetic field intensifies, the plunger moves linearly within the valve body, either opening or closing the flow orifice, depending on the valve’s design. Direct-acting valves rely solely on electromagnetic force to overcome media pressure and spring tension. In contrast, pilot-operated valves use electromagnetic force to control a small pilot orifice that regulates pressure differentials across a larger main valve diaphragm or piston.

When electrical power leaves the coil, the magnetic field collapses, and spring mechanisms return the plunger to its de-energized position. This return motion reverses the valve’s flow state, either opening a normally closed valve or closing a normally open configuration. The complete cycle typically occurs within milliseconds, enabling rapid system response to control signals.

Materials Used in Solenoid Valves

Brass construction offers excellent corrosion resistance, machinability, and cost-effectiveness for many standard applications. This material performs well in water, air, and various industrial fluids, while providing adequate strength for moderate-pressure applications. Brass components resist dezincification in potable water systems and maintain dimensional stability across typical operating temperature ranges. Water solenoid valve manufacturers, such as Solenoid Systems, frequently specify brass construction for residential and commercial plumbing applications where corrosion resistance and long-term reliability are paramount.

Stainless steel construction provides superior corrosion resistance, strength, and temperature tolerance for demanding applications. Various stainless steel grades accommodate a range of chemical environments, from mildly corrosive media to highly aggressive environments. The material’s strength characteristics support higher pressure ratings while maintaining excellent fatigue resistance under cyclic loading conditions. The food processing, pharmaceutical, and chemical industries commonly specify stainless steel solenoid valves due to their stringent hygiene and corrosion-resistance requirements.

Engineering plastics offer chemical inertness, lightweight construction, and cost advantages for specific applications. Materials such as PVC, CPVC, and PTFE provide exceptional chemical resistance to acids, bases, and solvents that would rapidly degrade metallic components. Plastic construction eliminates galvanic corrosion concerns in multi-metal systems while reducing overall system weight. These materials excel in chemical processing, water treatment, and semiconductor manufacturing applications where material purity and chemical compatibility are critical.

Applications of Solenoid Valves

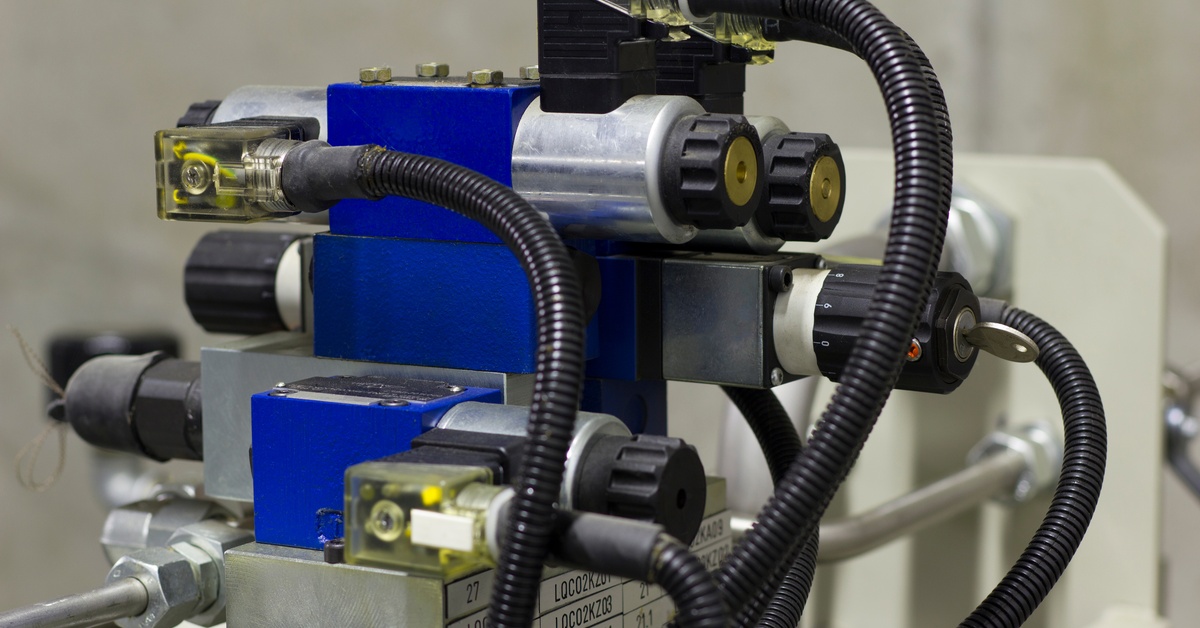

Industrial automation systems incorporate solenoid valves as fundamental building blocks for pneumatic and hydraulic control circuits. These applications require precise timing, reliable operation, and seamless integration with programmable logic controllers and other automation equipment. Manufacturing processes depend on solenoid valves to actuate cylinders, control conveyor systems, and regulate process fluid flows, with exceptional repeatability and speed.

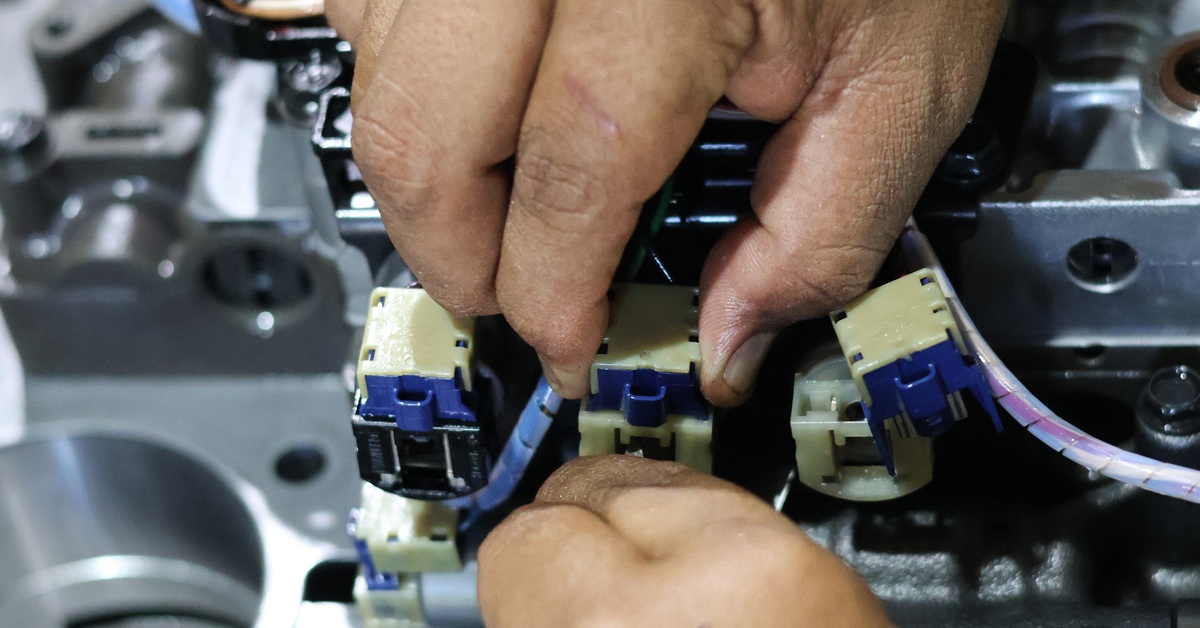

Automotive industry applications utilize solenoid valves throughout vehicle systems, from fuel injection control to transmission shifting mechanisms. Engine management systems rely on solenoid valves for precise fuel metering, exhaust gas recirculation, and turbocharger wastegate control. These applications demand compact designs, rapid response times, and the ability to withstand vibration, temperature extremes, and contaminated operating environments typical of automotive service.

Medical equipment applications require solenoid valves that meet stringent safety, reliability, and cleanliness standards. Dialysis machines, anesthesia systems, and laboratory analyzers incorporate specialized solenoid valves designed for biocompatibility and precise flow control. These applications often specify medical-grade materials, special cleaning procedures, and enhanced reliability testing to support critical patient care functions.

HVAC systems use solenoid valves to control refrigerant flow, hot-gas bypass, and liquid-line solenoids in commercial and residential applications. These valves must operate reliably across wide temperature ranges while maintaining leak-tight performance with various refrigerants and system pressures. Energy efficiency considerations drive demand for solenoid valves with low power consumption and minimal heat generation during continuous operation.

Maximizing Solenoid Valve Performance

Understanding solenoid valve components empowers engineers, technicians, and system designers to make informed decisions about valve selection, installation, and maintenance strategies. The interplay between electromagnetic coils, mechanical components, and fluid dynamics creates sophisticated control capabilities that modern industrial systems depend upon. Proper component specification, including materials, configurations, and operating parameters, directly impacts system reliability, efficiency, and total cost of ownership.

Advanced solenoid valve technologies continue evolving to meet increasingly demanding application requirements. Smart valve systems integrate diagnostic capabilities, proportional control, and communication interfaces to enhance performance monitoring and predictive maintenance. These technological advances build upon fundamental component designs while adding layers of sophistication that support Industry 4.0 initiatives and intelligent manufacturing systems.

Investing time in understanding these fundamental solenoid valve components pays dividends through improved system design, reduced maintenance costs, and enhanced operational reliability across diverse industrial applications.

Contact Solenoid Systems for all your solenoid manufacturing needs. Our expertise means we offer the best products to our customers. We look forward to hearing from you!