Waterproof solenoid valves protect core components across environments where moisture threatens performance, timing, and compliance. Automotive, medical, and industrial designers rely on sealed construction to extend service life and deliver consistent actuation without risk of short circuits or corrosion.

Across complex systems, water ingress leads to failures that cannot be reversed once degradation begins. Implementing sealed actuation creates measurable reliability improvements across applications that demand uninterrupted fluid control. The following examples showcase how waterproof solenoid valves outperform standard components in both durability and control accuracy.

Marine Fuel and Fluid Control Systems

Naval systems, commercial vessels, and offshore platforms use waterproof solenoid valves to regulate fluid transfer while withstanding constant vibration and harsh saltwater exposure. Inside engine compartments and bilge areas, ambient moisture frequently reaches levels that cause instant damage to unsealed electronics. Marine engineers often select IP67 or IP68-rated valves with corrosion-resistant housings and hermetic sealing to maintain long-term performance without manual intervention.

Ballast systems require fast, repeatable valve control across rapidly shifting loads, particularly during port maneuvers or turbulent conditions. Actuators that resist saltwater intrusion maintain critical stability without false signals or actuator delays. Unlike mechanical valves, solenoid-driven designs allow integration with onboard diagnostics and remote automation systems.

Fuel isolation circuits benefit from waterproof solenoid valves that block fluid movement immediately upon signal, even if splashing or immersion occurs. During emergency scenarios such as fire suppression or system breach, the margin for delay disappears. Technicians cannot rely on standard components when failure could endanger both personnel and equipment.

One of the top applications for waterproof solenoid valves appears in submerged or splash-prone fuel management environments where signal fidelity and housing durability directly protect engine safety. Systems that use sealed solenoids gain uptime consistency that traditional designs cannot deliver.

Medical Sterilization and Sanitation Equipment

Hospitals, laboratories, and sterilization plants often require waterproof solenoids inside steam-based disinfection units, autoclaves, and chemical washdown lines. Medical engineers depend on reliable valve actuation during thermal cycling, when both moisture and temperature fluctuate far beyond standard tolerance. A sealed solenoid valve maintains coil integrity and housing stability even during repeated exposure to high-pressure steam bursts.

In diagnostic or pharmaceutical environments, contaminated valves create unacceptable risk. Manufacturers eliminate moisture-related failures that compromise compliance with ISO and FDA sanitation protocols by integrating waterproof solenoids into drain and fill circuits. Automated rinse cycles in surgical washdown stations also demand sealed valves that operate independently of manual resets or external protection.

Vacuum cycle stabilization inside sterilization chambers requires precise fluid venting. Any delay in valve response during sterilization ruins the entire cycle and jeopardizes tools or bio-sensitive materials. Engineers rely on electronic valves to vent, refill, and regulate cycles without leakback from non-sealed interfaces.

Among the top applications for waterproof solenoid valves, medical disinfection systems depend on sealed actuation for uninterrupted operation during moisture-intensive sanitation sequences. High-pressure rinses and chemical sterilants no longer threaten the electronic core of modern valve systems.

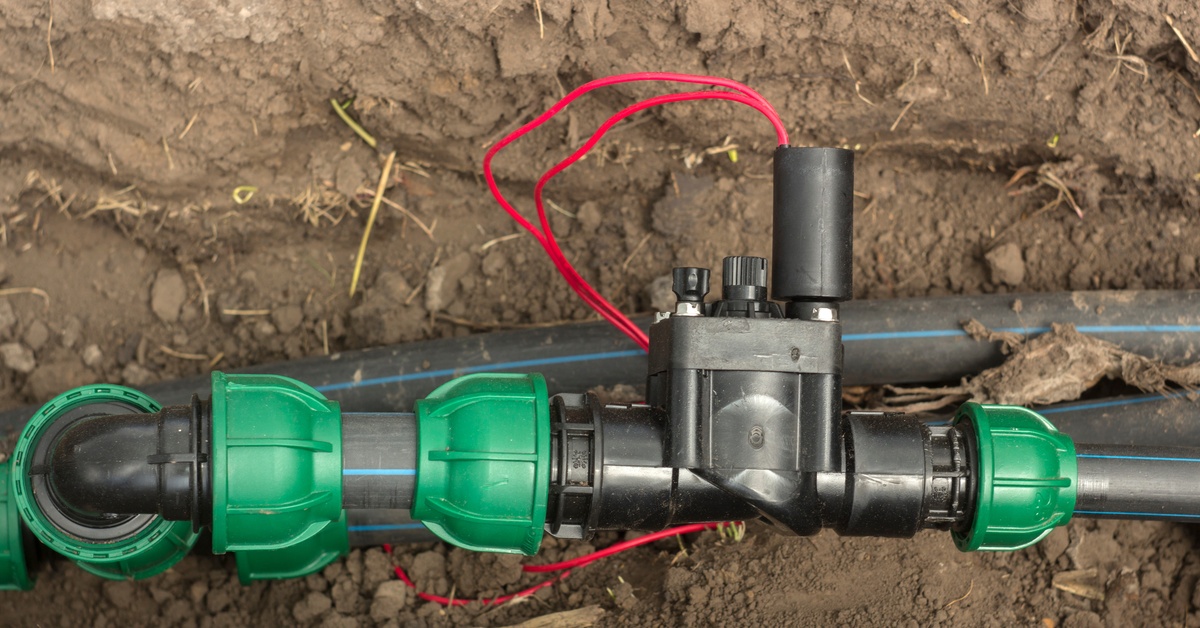

Outdoor Irrigation and Smart Agriculture Systems

Agricultural designers now integrate waterproof solenoids into remote irrigation networks, fertigation loops, and sensor-linked moisture control lines. Dust, UV exposure, and temperature fluctuations challenge even hardened electronic enclosures in outdoor environments. IP-rated valves preserve both actuation speed and signal responsiveness, even after prolonged exposure to seasonal elements.

In greenhouses, sealed solenoids modulate multi-zone spray systems based on environmental feedback from digital controllers. Without waterproofing, shorted signals delay response time or cause costly watering irregularities. Growers managing large-scale productions require components that operate continuously without supervision or field maintenance.

In orchards and vineyards, remote systems control pressure-based water delivery based on terrain and tree age. Solenoid-driven valves adjust output using predictive cycle data to reduce waste. Waterproof design keeps components operational across shifts in terrain runoff and exposure to particulate-filled water supplies.

Moisture-heavy environments like automated irrigation grids require solenoid valves that perform under rain, splash, and pressurized mist. Engineers select waterproof valves to minimize labor cost and maximize zone performance without frequent field adjustments or protective enclosures.

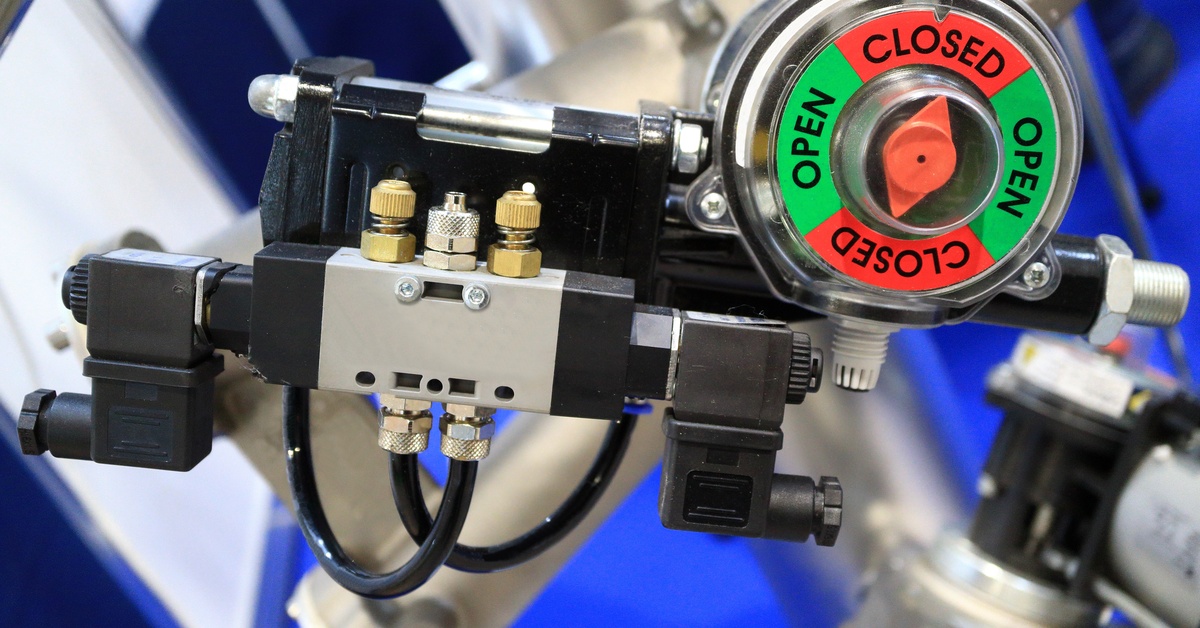

Industrial Washdown and Food Processing Equipment

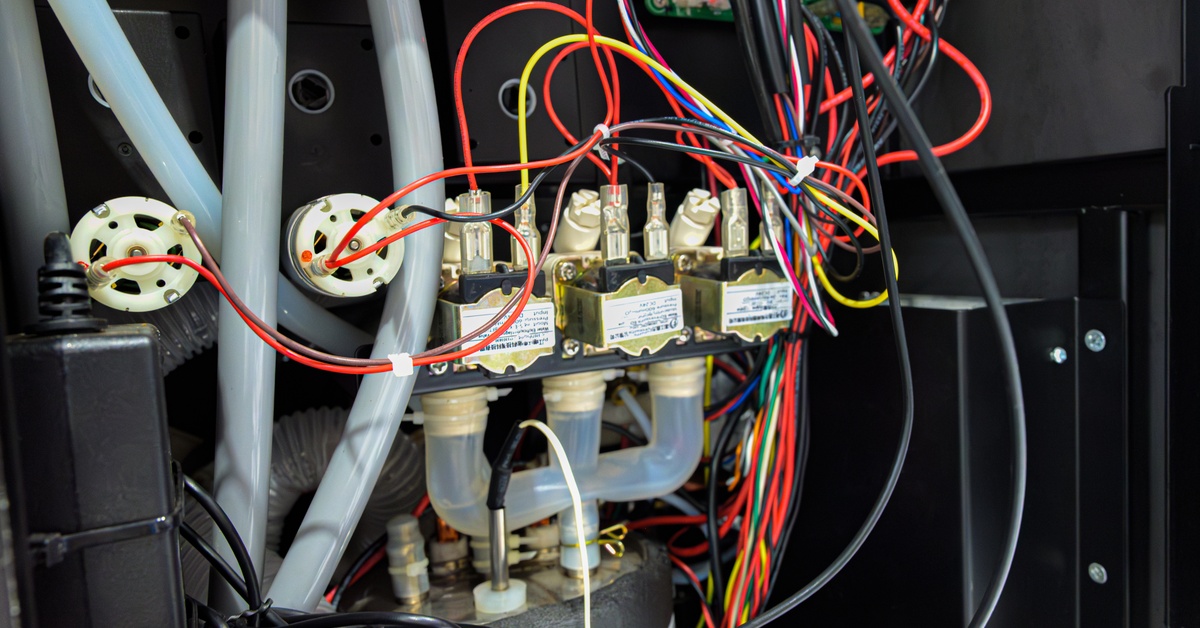

Food and beverage manufacturers incorporate waterproof solenoid valves into washdown-rated machinery, filling equipment, and clean-in-place (CIP) lines. Daily sanitation cycles blast hot water, caustic rinses, and steam directly over fluid control panels. Unsealed solenoids fail rapidly under repeat washdowns, even with minor gasket protection.

Filling machines use solenoids to start and stop beverage or paste flow in precisely timed sequences. Any moisture reaching signal wires or coil housing can throw off fill volume or trigger production downtime. Properly sealed valves operate even when spray hits actuators mid-cycle.

CIP systems require instant backflow prevention, venting, and zone isolation during cleaning cycles. Engineers install waterproof valves to ensure continuous function when cleaning agents or foam encase fluid control cabinets. Mechanical protection offers limited benefit once chemicals penetrate the housing.

At Solenoid Systems, we offer proportional solenoids that outperform standard designs in washdown-prone environments. Our sealed solutions maintain timing accuracy and feedback control under repeated exposure to moisture, temperature changes, and direct chemical impact—ideal for integrators building food-safe, water-resistant valve panels.

Automotive Engine Bay and EV Battery Management

Engineers designing electric and internal combustion vehicles often implement waterproof solenoid valves to manage thermal systems, vacuum regulation, and transmission actuation. Inside modern engine bays, road spray, rapid temperature changes, and electromagnetic interference create hostile conditions for unsealed solenoids. Automotive-grade waterproof valves perform critical shutoff, reroute, and bleed operations during both startup and full-load runtime.

Turbocharged platforms use solenoids to regulate boost pressure and blow-off actuation. Moisture reaching the core of the solenoid can delay response or lead to drift under repeat cycles. Waterproofed assemblies eliminate this risk without resorting to heavy shielding or bulky enclosures.

EV battery platforms demand thermal management using dielectric fluid or sealed coolant loops. Solenoid valves direct coolant across active zones with microsecond-level control. Sealed valves prevent leakback or arc potential from reaching other high-voltage electronics near the valve housing.

Reliability in high-heat engine conditions or cold-start scenarios requires fluid control devices that block water and chemicals. Without waterproof solenoids, under-hood systems risk cascading failure from a single intrusion point. Automotive engineers install sealed valves to preserve performance and reduce warranty issues related to component drift.

Find the Right Solenoid for the Job Today

Engineers who value precision under pressure often overlook how moisture quietly degrades valve performance over time. Sealed solenoid systems eliminate that risk from the start.

At Solenoid Systems, we build waterproof and proportional solenoids that outperform in marine, medical, and industrial washdown applications. Reach out to discuss how our components can meet your design requirements without sacrificing control, speed, or system integrity.