Solenoid valves manage the flow of liquids or gases in automation systems, fluid control processes, HVAC systems, and medical devices. Response time, or the speed at which these valves operate, determines how effectively they meet performance demands. Response times in solenoid valves are important for other reasons. Let’s assess their long-term benefits.

Understanding Response Times

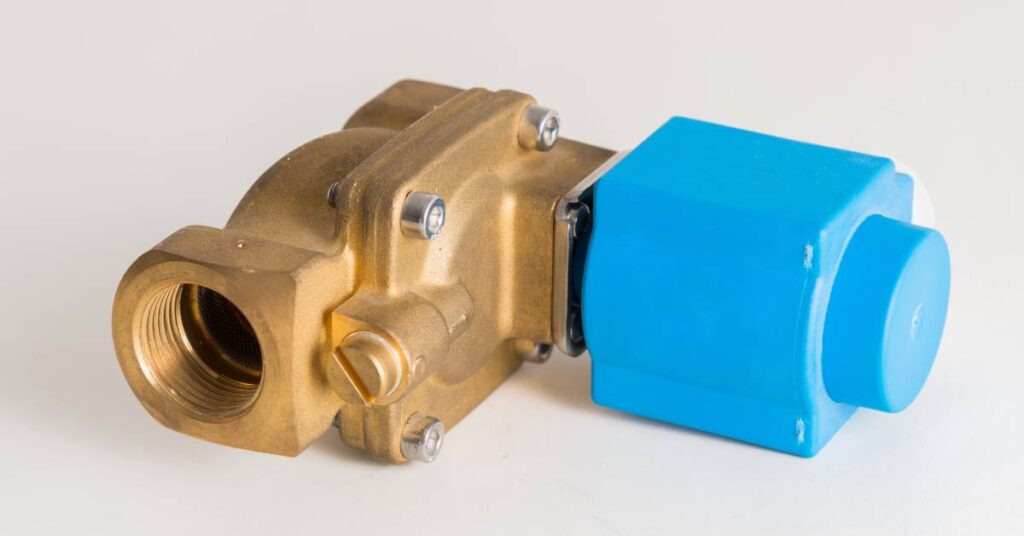

Response time refers to the period it takes a solenoid valve to complete actuation once triggered. This process begins when an electrical signal energizes the valve’s coil, creating a magnetic field that moves internal components, such as the plunger or diaphragm.

Engineers calculate this time from the moment the signal sends to when the valve fully opens or closes. The process involves electrical and mechanical delays—electrical represents the coil’s energization time and mechanically reflects how long the moving parts take to shift.

High-speed sensors measure these phases in milliseconds. For example, if energization requires 5 milliseconds and actuation 8 milliseconds, the valve’s total response time measures 13 milliseconds. Moreover, several factors influence a valve’s response speed, including the coil design, weight, and environmental conditions, such as fluid viscosity and pressure. Heavy materials or thick fluids can reduce speed and create operational inefficiencies if no one optimizes the conditions.

Engineers evaluate these parameters carefully during valve selection (or creation) to ensure compatibility with system requirements. For instance, some engineers ask solenoid manufacturers to customize valves in order to overcome challenges that standard valves cannot address.

Enhances System Efficiency

Faster response times guarantee that systems perform efficiently with minimal operational delays. For example, solenoid valves control material flow in packaging industries, and delays could cause bottlenecks and reduce production speed.

Quick valve operation supports high-cycle applications, such as robotics or dispensing systems, where repetitive tasks demand fluid, uninterrupted movement. Lagging responses can drain energy, as valves might stay partially open longer than needed and consume resources without measurable output.

Systems that depend on fluid control maintain their peak throughput when valves respond swiftly. Overall, the faster the components work, the smoother the operations across interconnected systems.

Reduces System Downtime

Operational delays can ripple through an industrial system when solenoid valves fail to respond quickly. High-stakes environments, such as power plants and oil refineries, demand precision in fluid and gas management.

A delayed valve could disrupt a carefully calibrated process and halt systems tied to production goals. For instance, valves that regulate coolant flow in power plants must respond immediately to avoid overheating equipment, which could force an emergency shutdown. Every missed moment increases the risk of compromised operations.

Extends the Life of Connected Components

Response times in solenoid valves are important because systems endure less stress when valves respond as expected. Slow response valves can cause inconsistencies, which place excessive physical demands on pumps, pipes, or control actuators.

This constant strain accelerates wear, undermining the reliability of the entire setup. For example, in food processing factories, sustained delays in valve performance can disrupt fluid pressure levels and cause machinery to overcompensate. Systems with responsive valves operate within their intended parameters, improving the overall sturdiness of every connected element.

Improves Emergency Response Proficiency

Some systems require solenoid valves that can react swiftly during unexpected situations to maintain control. For instance, a gas leak in a distribution pipeline must stop quickly to avoid endangering equipment, personnel, or the environment.

A slow valve delays containment efforts, which can lead to mechanical damage or safety incidents. High-performing valves support emergency measures, such as fuel supply cutoffs, to reduce risks, preserve equipment, and improve recovery times.

Increase Safety in Critical Applications

Medical devices, such as ventilators, depend on solenoid valves for precise airflow regulation. When treating patients with respiratory conditions, any delay in valve activation can affect life-sustaining oxygen delivery.

A slow valve response won’t maintain stable treatment outcomes and can harm patients. Fast-reacting valves ensure that air or medical gases flow immediately and properly, keeping devices aligned with therapeutic requirements.

High-stakes applications, like aerospace or fire suppression systems, require valves that can work without hesitation, too. A delayed valve in a fire suppression system could allow small fires to spread, endangering facilities and personnel.

Similarly, mission-critical aerospace systems rely on timely oxygen regulation during flight emergencies. Components with fast activation mitigate risks under pressure and support safety measures to prevent catastrophic outcomes.

Prevents Equipment Damage From Pressure Surges

Fluid control systems face pressure surges when valves fail to respond quickly, especially in pipelines managing liquid or gas transfers. Delays increase the chance of pressure spikes, which can burst pipes or destabilize storage tanks. Responsive valves maintain steady pressure levels, extending the lifespan of connected machinery and reducing the likelihood of mechanical faults.

Minimizes Risks From Fluid Hammer Effects

Fluid hammer occurs when a fluid’s flow halts or changes direction abruptly. This leads to shockwaves that may damage pipelines or system equipment. Solenoid valves with slow response times contribute to this damaging phenomenon in liquid transport systems, such as those in irrigation or industrial cooling setups.

Fast-acting valves reduce the risk of fluid hammer so that flow transitions are smooth and controlled. Operators avoid sudden failures through effective valve integration, improving long-term system reliability.

Supports Innovation and Modern Applications

Emerging industries continue to push boundaries with technologies that demand faster and more reliable system operations. Autonomous vehicles, for example, rely on precise pneumatic or hydraulic systems for suspension adjustments or energy storage.

Similarly, space exploration technologies use safety-critical valves to manage fluid transfers in cryogenic fuel systems. Modern solenoid valves extend compatibility to high-tech applications, ensuring they keep pace with evolving needs across multiple sectors.

Accelerate Renewable Energy Systems

Valves support renewable energy systems where timing impacts performance. For example, green hydrogen production involves managing gas pressures during storage and transfer. High-speed valves support stability and prevent safety risks or system losses during these procedures.

Similarly, wind and hydroelectric turbines need responsive fluid controls to optimize energy production under fluctuating conditions. Modern renewable technologies depend on precise and reliable valve operations to meet energy production goals.

Aligns With AI-Driven Processes

Artificial intelligence (AI) has introduced real-time control to the logistics and healthcare industries. AI-powered systems require immediate input and output responses to deliver actionable insights. For instance, advanced manufacturing facilities using AI-monitoring systems depend on accurate valve control to optimize processes, such as filling, sorting, or packaging. Delayed valve action compromises these systems and reduces their effectiveness.

Enhances User Satisfaction

End-users expect reliable systems that operate without interruptions, especially in industries where consistent performance directly impacts their outcomes. For example, beverage manufacturers need uninterrupted bottling functions.

Poor valve performance leads to costly slowdowns that frustrate customers and operators alike. Quick response valves facilitate seamless operations, preserving the integrity of the user experience. Ultimately, satisfaction stems from systems meeting or exceeding user demands.