Solenoid Prototyping

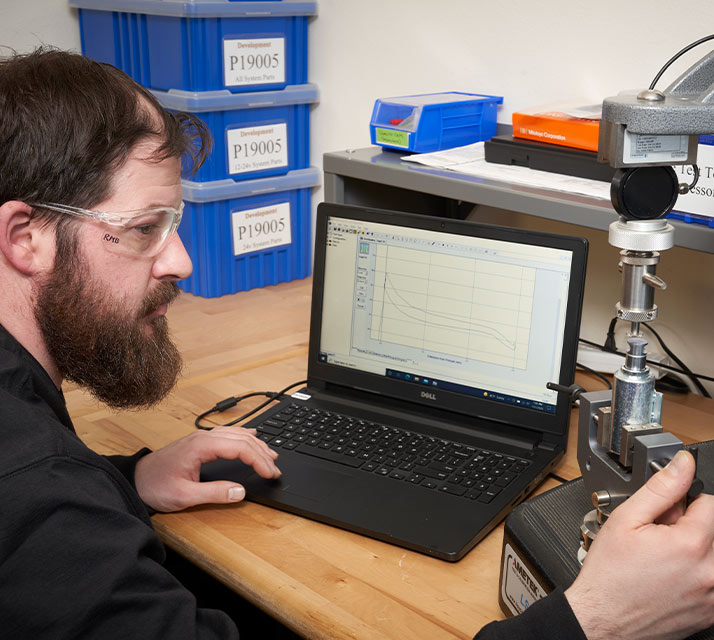

At Solenoid Systems, we proudly offer an unparalleled solenoid prototyping service featuring the industry’s most comprehensive array of testing capabilities. Our advanced engineering lab, fully equipped with experienced engineers, provides a secure environment for developing and testing custom solenoid solutions. We excel in tailoring our services to meet the specific needs of our clients, ensuring flexibility and customization at every step.

Unlike other providers, we focus on customization, and we adapt testing and prototyping to meet new requirements or specifications with ease. Our stringent quality assurance processes and advanced measurement technologies back every project, guaranteeing that all components meet the highest quality standards.

Solenoid Solutions operates a fully equipped engineering lab to build and test prototypes and components from quality suppliers. Our prototype testing capabilities include:

- Precision Solenoid Force Testing: We accurately measure the force exerted by solenoids, ensuring optimal performance and compliance with design specifications.

- Solenoid Response Time: Our team assesses the speed at which solenoids activate and deactivate, providing critical data for applications that demand rapid response.

- Electrical Testing (HiPot, Insulation Resistance, Inductance, and Resistance): We conduct comprehensive electrical tests to evaluate the safety and efficiency of solenoids, safeguarding against electrical failures.

- Valve Testing (Pressure, Flow, and Response): Our experts test valves under various conditions to verify pressure thresholds, flow rates, and response times, ensuring reliable operation in diverse environments.

- Durability testing: We stress-test solenoids to determine their lifespan and resilience under typical and extreme conditions, guaranteeing long-term reliability.

- Thermal Cycle and Shock Testing: Our lab subjects solenoids to temperature fluctuations and mechanical shocks to assess their robustness and performance stability in challenging applications.

Our Process

We set the stage for successful solenoid, valve and solenoid system development by constructing a comprehensive prototype assembly process and control plan. From our advanced coil winding capabilities to sophisticated measurement technologies, we assure performance is as expected.

Importance of Quality Prototyping

High-quality solenoid prototyping helps create components that meet the highest standards of precision and performance. Investing in our services reduces the risk of costly errors and ensures the seamless operation of your solenoid systems, meeting all desired specifications.

Our advanced prototyping capabilities offer you the most comprehensive testing options in the industry. We deliver excellent detail and accuracy, allowing you to refine designs and enhance functionality before full-scale production. This thorough approach boosts the reliability of your solenoids and speeds up the time to market, giving you a competitive edge.

We use outstanding solenoid testers to quickly and efficiently test solenoid prototypes, ensuring they perform under various conditions. Accurate testing prevents potential failures and addresses any design flaws before they escalate.

Our goal is to empower your business with solenoid solutions that combine quality, reliability, and innovation, ensuring your satisfaction and success in every application. Please contact us today to learn more about our prototyping services. We look forward to working with you!