Solenoid Manufacturer

We Specialize in Manufacturing

With over three decades of engineering excellence, Solenoid Systems delivers custom solutions for the most demanding industrial, aerospace, and medical applications. As a premier pneumatic solenoid valve manufacturer, we specialize in everything from high-volume serial production to intricate coil winding and low-pressure molding. Our team collaborates directly with you to design efficient manufacturing processes that meet rigorous industry standards. Whether you require robust resistance welding or advanced overmolding for harsh environments, we ensure every component exceeds performance expectations. Make sure you partner with us to drive innovation and secure reliable results for your next project.

Diverse Industry Experience

Our extensive industry experience makes us the top solenoid manufacturer. From automotive production lines to the precision requirements of aerospace applications, we understand the distinct challenges and opportunities within each sector. Our experience allows us to deliver tailored solutions that meet industry-specific standards and exceed expectations

Our Manufacturing Expertise include:

- Serial Production (high and low volume) – Our facilities can handle high-volume or low-volume production. Our flexibility ensures that we can scale production to meet your specific requirements.

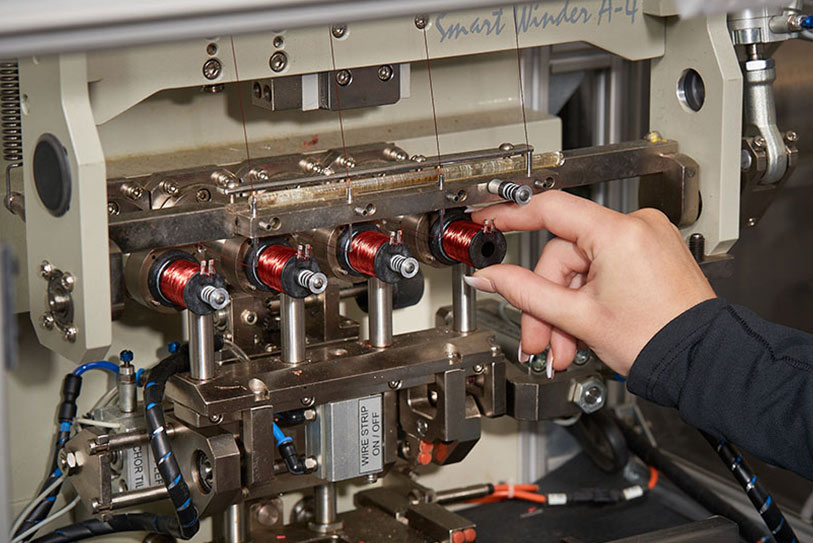

- Coil Winding – Our coil winding technology is state-of-the-art, providing precise and reliable results for every application.

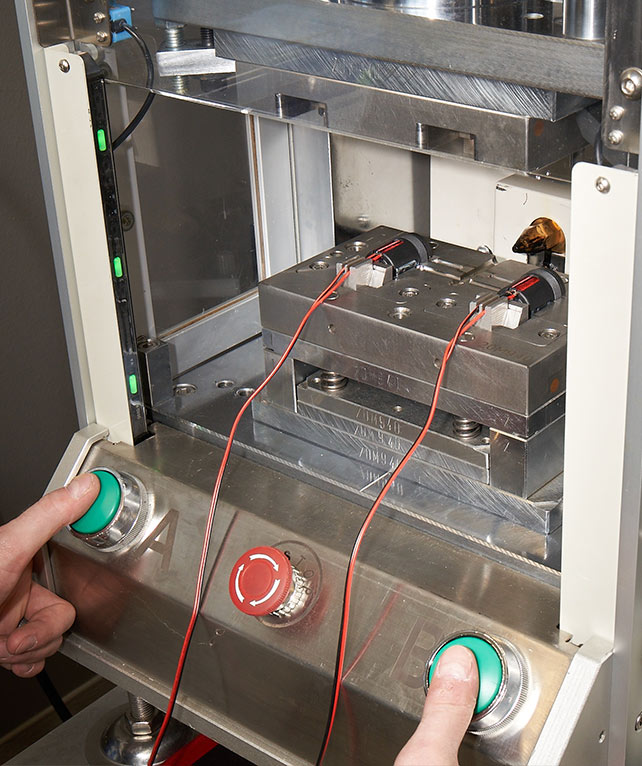

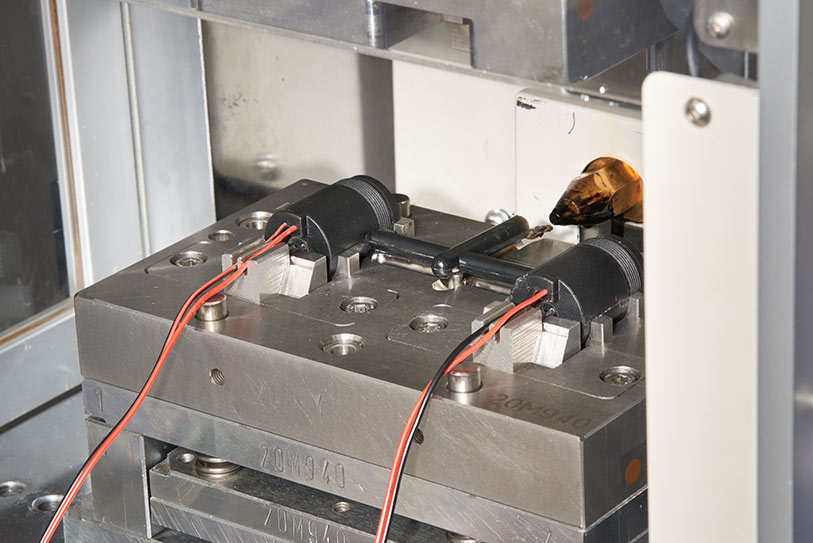

- Wire Termination (Resistance Welding) – We utilize advanced resistance welding techniques to ensure secure and durable wire termination, critical for the longevity and reliability of solenoids.

- Coil Overmolding – Our expertise in coil overmolding guarantees robust protection and insulation of coils, enhancing performance and durability.

- Low-Pressure Molding – We offer low-pressure molding services to provide additional protection and stability to sensitive components.

- Manufacturing Process Design – Our team excels in designing efficient and effective manufacturing processes that meet your product’s specific needs.

Custom Solutions and Innovation

Innovation is at the heart of Solenoid Systems. As premier solenoid manufacturers, we dedicate time to developing custom solutions that meet and anticipate our clients’ evolving needs. Our team collaborates with you to understand your industry’s challenges and create solenoids that offer outstanding performance. Whether you need specialized configurations or unique functionalities, we have the expertise to deliver the right solutions.

Commitment to Excellence

We reflect our commitment to excellence in every area of our operations. From the first design phase to final production, we ensure that every solenoid system we manufacture meets the highest quality and performance standards. We undergo rigorous testing and quality assurance processes to guarantee that our products deliver consistent and reliable results, even in the most demanding environments.

As the leading solenoid valve manufacturer, we continuously innovate and improve to provide cutting-edge solutions that exceed industry standards and fulfill your specific needs.

Join the Leaders in Solenoid Technology

Solenoid Systems is your innovation partner. Our expertise, comprehensive capabilities, and commitment to custom solutions make us ideal for industries seeking high-performance solenoids. We’re the water solenoid valve manufacturers you can trust. Contact us today to explore how we can meet your unique needs and drive your projects to success.

We look forward to collaborating with you.

Our Manufacturing Processes & Services

Serial Production

Solenoid Systems leverages over 30 years of manufacturing experience in Coil Winding, Resistance Welding, Overmolding and Assembly Processes. Our U.S. based facility supports low to high volume production, ranging from manual to highly automated processes.

Coil Winding

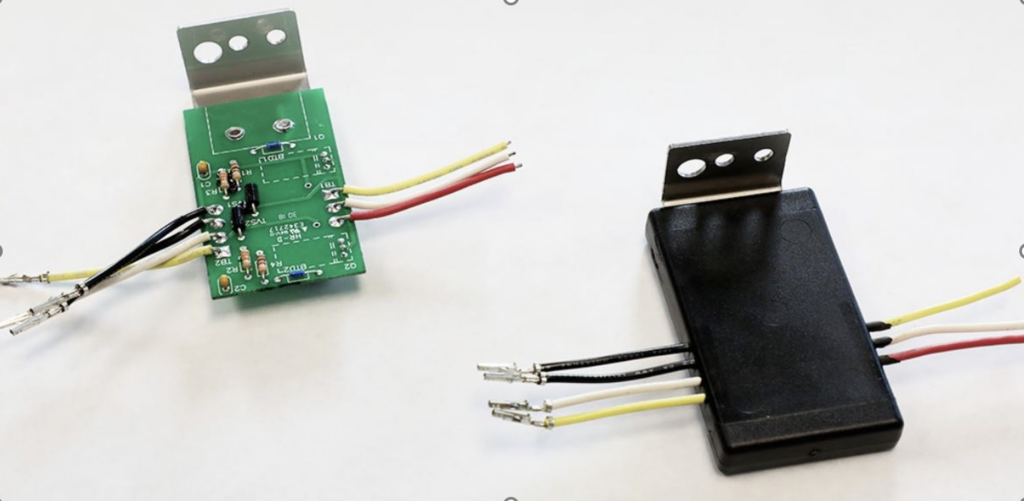

Coil Overmolding

Solenoid Systems uses a a Low Pressure Molding Process to Overmold our coils. The Low Pressure Molding process encapsulates parts safely providing waterproofing and protection against temperature extremes, harsh chemicals, shock and vibration.

Wire Termination - Resistance Welding

Resistance Welding Magnet Wire to Terminals or Lead Wires has many advantages over soldering:

- Produces Stronger joints

- Higher Temperature rated Magnet

- Can process Higher Temperature Magnet Wire Insulation

- Wire Insulations can be used

- Repeatable, does not rely on an operator’s skill

- Quality Control, weld parameters can be monitored to verify a quality joint

- Can be used on a variety of materials

Low Pressure Molding

Solenoid Systems provides short and long-term overmolding services and contract manufacturing.

Low Pressure Molding encapsulates parts safely, providing waterproofing and protection similar to traditional technologies such as potting, sealing or conformal coating but with faster processing times at a fraction of the cost.