Industrial automation represents a significant leap forward in manufacturing and process control. By integrating sophisticated machinery and intelligent systems, companies can achieve levels of productivity and precision once thought impossible. The effectiveness of these automated systems, however, often depends on the performance of their individual components. The ability to control the flow of fluids and gases with speed and accuracy is fundamental to many industrial processes. Continue reading to discover how solenoid valves enhance industrial automation efficiency.

How Solenoid Valves Work

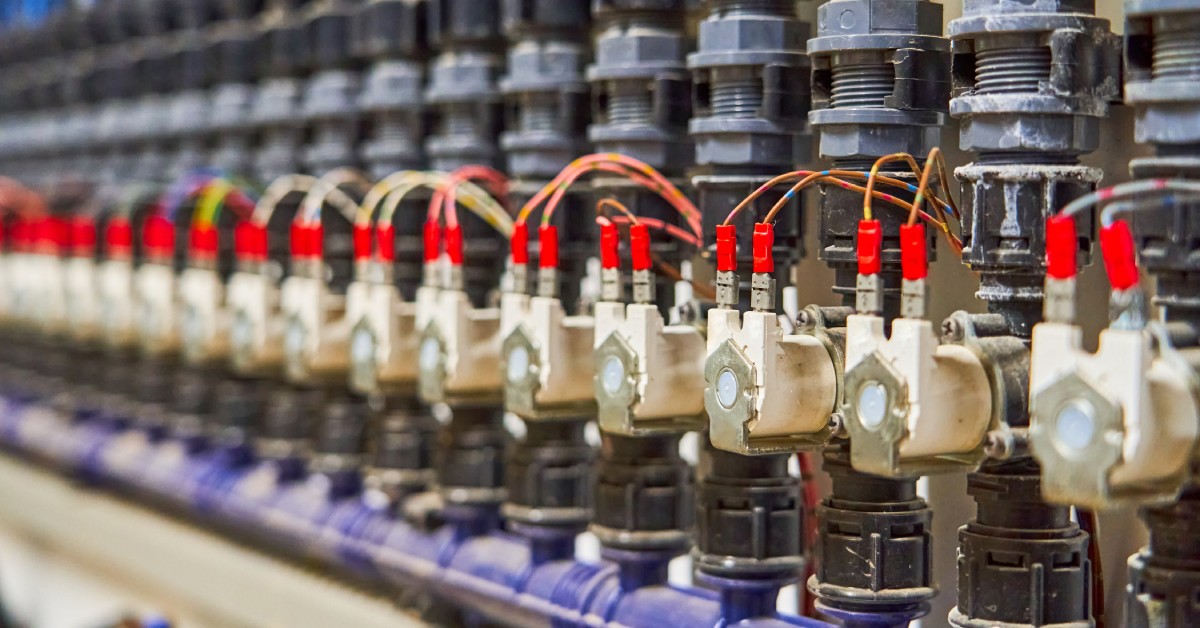

At the heart of many automated fluid control systems is a device that converts electrical energy into mechanical motion. This device consists of a few key parts: an electromagnetic coil, a plunger or armature, and a valve body containing one or more orifices. When an electric current passes through the coil, it generates a magnetic field. This magnetic field exerts a force on the plunger, causing it to move. This movement either opens or closes the valve, controlling the flow of a liquid or gas. The simplicity and effectiveness of this electromechanical principle make these valves incredibly reliable for automated applications.

There are several types of these valves, each designed for specific operational requirements. The most common are direct-acting and pilot-operated. Direct-acting valves use the magnetic force from the coil to directly open or close the valve orifice. This design is straightforward and provides a fast response, making it ideal for applications that require quick action but do not involve high flow rates or pressures. Pilot-operated valves, on the other hand, use the fluid line pressure to assist in opening and closing the valve. This design allows for the control of much higher flow rates and pressures with a smaller, more energy-efficient coil. The choice between these types depends on the specific needs of the application, including factors like pressure, flow rate, and response time.

Benefits of Solenoid Valves in Industrial Automation

The integration of solenoid valves into industrial automation systems provides substantial benefits.

Enhanced Efficiency

One of the most significant advantages is enhanced efficiency. These valves offer rapid response times, often activating in milliseconds. This speed enables precise, immediate control over processes, minimizing waste and maximizing output. For example, in a bottling plant, the exact amount of liquid can be dispensed into each container, reducing spillage and improving consistency. This level of precision is critical in industries where even minor variations can have a major impact.

Cost Savings

Cost savings are another key advantage. The efficiency of solenoid valves translates directly into lower operational expenses. Their precise control reduces material waste and energy consumption. Furthermore, high-quality solenoid valves will provide durability and require minimal maintenance, which lowers long-term ownership costs. Their reliability also means less downtime for repairs, leading to more consistent production schedules and greater overall productivity.

Increased Reliability

Increased reliability is also a hallmark of well-designed solenoid valves. Built with robust materials and engineered for demanding industrial environments, these components have a long operational lifespan. Their simple mechanical design with few moving parts reduces the likelihood of failure. This dependability is essential in critical applications where a system failure could have serious consequences, such as in medical equipment or aerospace systems. When you can count on a system to perform consistently, it builds confidence and supports a more stable, predictable operational workflow.

Custom Solenoid Solutions for Specific Applications

While standard off-the-shelf components can work for many general-purpose tasks, they often compromise performance. Custom solenoid solutions, however, are engineered to meet the exact requirements of a specific application. This tailored approach delivers optimized performance that generic parts cannot match. For instance, a custom valve can have particular materials to handle corrosive fluids or have the configuration to operate within a very specific temperature range. This optimization leads to greater efficiency, longer service life, and improved system performance.

Solenoid Systems specializes in developing these custom solutions. Our expertise allows us to create valves that deliver precision control in a wide array of applications. Our custom products are already at work across diverse fields, from managing water flow in large-scale resource systems to positioning sensitive instrumentation on satellites. In the medical field, our custom designs are driving new, advanced procedures that demand the highest levels of accuracy and reliability. Other applications include modulating the flow of cryogenic gases and recirculating engine exhaust. The possibilities are virtually endless.

The Engineering and Development Process

At Solenoid Systems, we act as a partner to fully understand our clients’ needs and develop a customized solution that perfectly fits their application. Our approach begins with a deep dive into the client’s requirements. We collaborate closely with your team to define the operational parameters and performance goals. This partnership forms the foundation of our design and development process, which leverages three decades of engineering talent and a history of successful results.

We utilize a Virtual Development Platform powered by advanced simulation technologies and proven development processes to deliver highly engineered solutions. This platform allows us to model and test designs in a virtual environment, refining them for optimal performance before building a physical prototype. This iterative process helps solve design challenges early and brings your ideas to life efficiently. We function as an extension of your development team, creating custom solenoids, solenoid valves, and complete systems that meet the demands of the most challenging applications.

Our US-based manufacturing facility supports the entire production journey, from prototype to full-scale production. With over thirty years of manufacturing experience, we have extensive capabilities in coil winding, resistance welding, overmolding, and complex assembly processes. Our facility can handle both low- and high-volume production, utilizing everything from manual assembly for specialized units to highly automated processes for larger orders. This integrated approach from design to production allows us to maintain strict quality control and deliver products that perform as expected.

Shaping the Future of Automation

The role of solenoid valves in industrial automation is undeniable. They offer a powerful combination of speed, precision, and reliability that drives efficiency and reduces operational costs. As industries continue to push the boundaries of what is possible, the demand for components that can deliver higher performance in more challenging environments will only grow.

Achieving optimal results in these advanced systems requires moving beyond one-size-fits-all solutions. Custom-engineered solenoid valves provide the tailored performance needed to unlock the full potential of modern automation. To learn more about how our custom solenoid solutions can elevate your operations, contact Solenoid Systems to discuss your application.