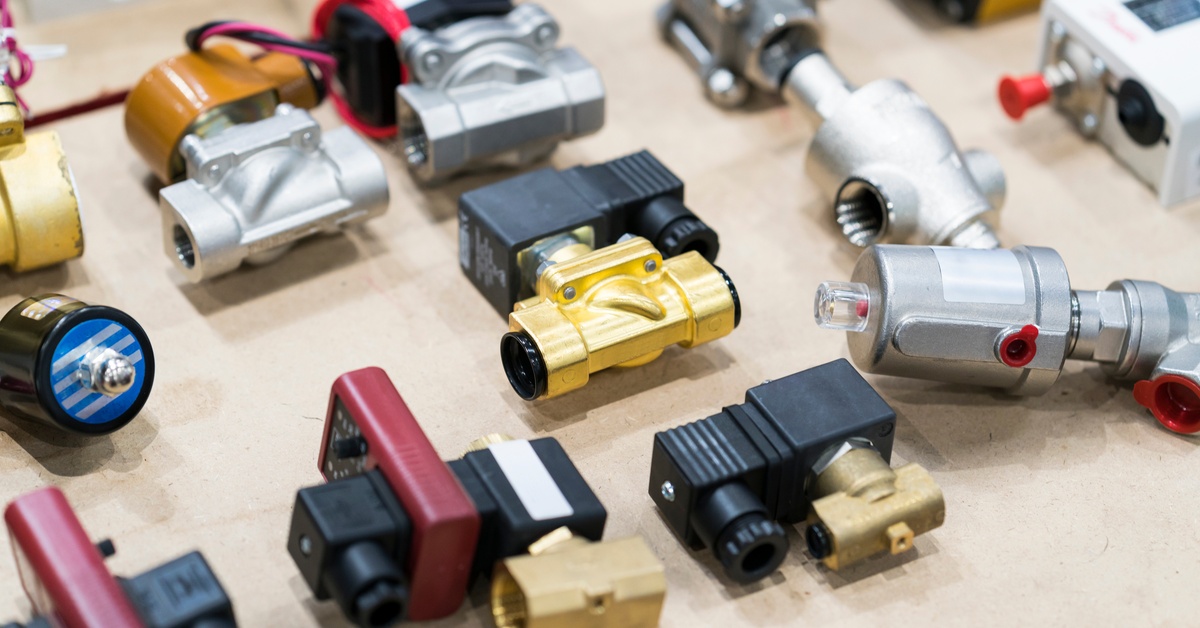

Solenoid valves power the precision control behind countless industries regulating fluid flow in fuel systems, directing gases in medical ventilators, and managing pressure in factory automation. Engineers depend on solenoid valves to deliver rapid actuation, maintain leak-free sealing under pressure, and withstand vibration, heat, and chemical exposure in critical systems.

Yet, too often, project teams enter specification phases with false assumptions. Missteps don’t always come from inexperience—they often come from relying on outdated beliefs or treating solenoids as generic, passive devices. Here are some key facts about solenoids, so you can make the best decisions for your operations.

All Solenoids Are Functionally Interchangeable

Treating all solenoids as interchangeable leads to control instability and fluid delivery problems. Direct-acting solenoids behave differently from pilot-operated or proportional models, even when their fittings and specs appear similar on paper.

A solenoid optimized for on/off binary control cannot deliver smooth modulation in a closed-loop feedback system. Likewise, a pilot-operated valve will stall entirely in low-pressure conditions if engineers don’t provide adequate differential pressure.

Design teams must understand actuation forces, orifice geometry, and required pressure drop before choosing a valve. A direct-acting solenoid offers high reliability in low-pressure pneumatic systems but wastes power if oversized for the flow.

Proportional solenoids offer nuanced control in medical dosing or microfluidics but demand high-fidelity signals and tight electrical tolerances. Each design serves a specific purpose, and matching the architecture to the system goal determines success.

More Voltage Always Means More Power

Engineers sometimes believe a higher voltage rating automatically increases solenoid performance. Coil strength derives from winding count, wire gauge, magnetic saturation, and flux density—not from voltage alone.

A 24V solenoid may actually deliver less force than a well-designed 12V model in real-world scenarios. Voltage affects energy input, but that energy must convert into usable magnetic pull through carefully controlled geometry.

Pushing voltage beyond the coil’s optimal design window creates problems, not gains. Excess input drives heat buildup, shortens insulation life, and introduces EMI that interferes with nearby electronics.

Thermal rise increases sharply in enclosed environments where ventilation is limited, as in aerospace and robotics housings. Performance requires balance, not brute force, and higher voltage often signals poor fit rather than added capability.

Custom Solenoids Take Too Long and Cost Too Much

Teams sometimes default to off-the-shelf solenoids because they believe customization will delay schedules or raise costs. That misconception leads to forced integration, added support brackets, or auxiliary regulators to compensate for imprecise flow or mounting fit. Off-the-shelf components often introduce more variables, not fewer, especially when tolerances are tight or when space is constrained.

At Solenoid Systems, we provide custom solenoid valve designs that fit any business’s unique needs. By tailoring voltage, response time, material compatibility, and coil geometry, we deliver components that drop directly into the intended assembly.

Engineers save space, reduce cabling, and eliminate external flow restrictors by choosing purpose-built actuators. Common misconceptions about solenoid valves often cause design teams to assume catalog parts will simplify system integration. However, that assumption regularly increases failure risk and long-term costs.

Solenoids Can Handle Any Fluid if PSI Ratings Match

Selecting solenoids based only on pressure ratings creates major compatibility risks. Engineers sometimes believe that if a solenoid can withstand system PSI, it must tolerate the fluid itself.

That’s rarely true since materials such as Buna-N, Viton, or EPDM each resist different chemicals. Without matching seals and plungers to specific media, even the best-rated solenoids fail due to chemical attack or elastomer swelling.

Medical sanitization fluids, ammonia-based coolants, acidic cleaners, and oil additives all react differently with rubber and plastic components. Compatibility charts and historical chemical test data must guide material selection, not just flow specs or temperature curves.

Long-term durability comes from resisting degradation over thousands of cycles, not just surviving startup. Mismatched materials often result in valves that stick, leak, or break down prematurely under continuous exposure.

Solenoids Don’t Interact With the System

Treating solenoids as electrically isolated devices creates design flaws in timing, noise management, and signal fidelity. Engineers sometimes believe that once powered, the solenoid operates in isolation without affecting system behavior. But the actuation curve, coil field bleed, and pressure response all interact with sensors, logic controllers, and fluid pathways. Solenoids play active roles in both mechanical and electrical domains.

In integrated systems such as ventilators or CNC machines, a delayed valve response may disrupt timing across feedback loops. An unshielded coil can corrupt analog sensor data, forcing false readings or unexpected actuator stalls.

Engineers must simulate solenoid behavior in context, not just as an isolated part. Interaction defines reliability—and well-matched timing across the system improves overall responsiveness.

IP Ratings Eliminate the Need for Maintenance

Engineers sometimes treat IP-rated solenoids as maintenance-free simply because they carry environmental sealing. That logic fails in systems subject to vibration, long duty cycles, or rapid thermal fluctuation. Even fully sealed units develop coil fatigue, spring shift, or plunger misalignment over time.

Long-term reliability comes from system-level maintenance planning, not seal ratings. In industrial automation systems, operators must schedule periodic actuation testing and cycle tracking—even for hermetically sealed valves.

Aerospace solenoids may require recalibration based on flight hours, while food-grade actuators might call for replacement after a set number of steam-cleaning intervals. Ignoring wear cycles reduces confidence, even when hardware looks intact.

Quoted Response Times Reflect Real-World Speed

Spec sheets often quote fast electrical response times, but figures rarely include full mechanical actuation and flow stabilization. Engineers who assume the quoted 10 ms time includes full travel distance and pressure normalization may design timing systems that fire too early or too late. Signal recognition, magnetic field buildup, armature travel, and damping resistance all contribute to total functional delay.

Precision systems such as inkjet printers, automated pipetting stations, or robotic grippers depend on real-world response times instead of coil excitation speeds. The difference between electrical signal reception and fluid flow stabilization may exceed 100 ms depending on internal spring force and fluid viscosity.

Designers must validate solenoid behavior under actual load and pressure, not assume lab-grade values match field results. Real-world testing confirms whether timing tolerances fall within spec.

Once You’ve Specified a Solenoid, There’s No Need To Reevaluate

Engineers often reuse solenoid models across projects, assuming previous success guarantees future performance. That belief turns into a blind spot, especially when pressure conditions, voltage control, or system timing evolve.

Designs optimized five years ago may no longer match today’s speed requirements, signal voltages, or power constraints. Common misconceptions about solenoid valves undermine innovation by reinforcing outdated habits that don’t reflect real-world system demands.

Even minor changes in system layout—such as longer tubing, tighter flow tolerances, or proximity to new electronics—warrant reevaluation. Faster control loops, smarter feedback systems, and advanced materials all affect how the solenoid interacts with the environment.

At Solenoid Systems, we help industry leaders rethink outdated beliefs and replace them with application-specific insight. Our custom solenoid valve solutions power devices across aerospace, medical, and advanced manufacturing environments. Reach out today to build a smarter actuator for your system.