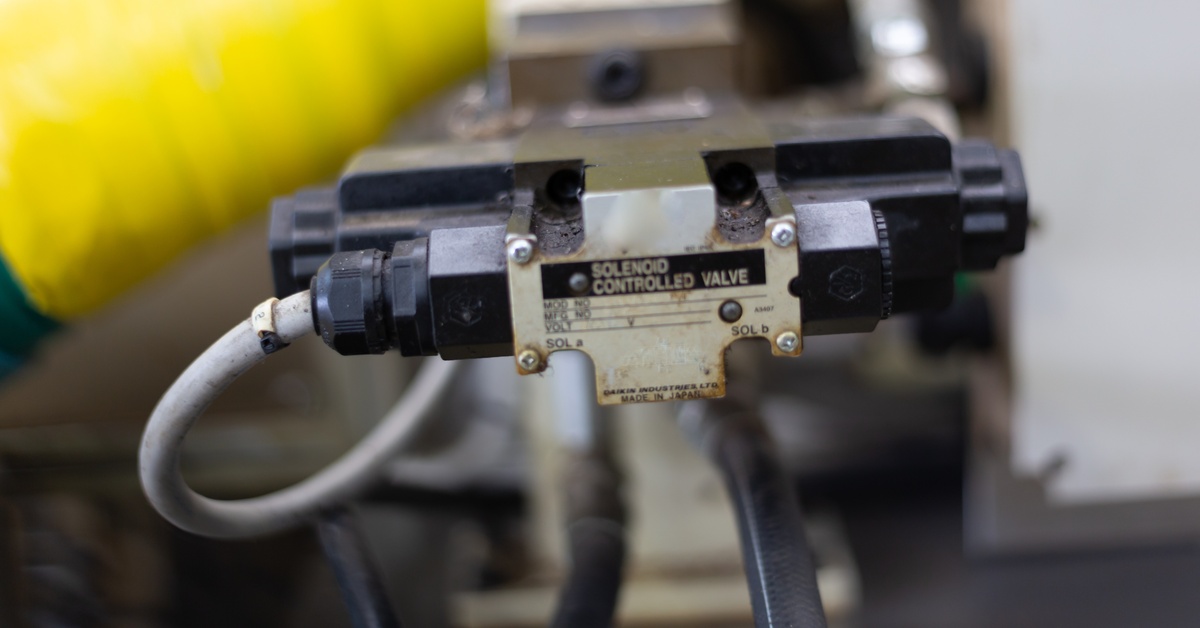

Precision is essential in industries that demand seamless operation, minimal error rates, and compliance with stringent requirements. Solenoid valves aid in this precision for certain sectors by controlling fluid and gas flow with unparalleled accuracy and reliability.

Incorporating custom valve designs further enhances operational performance, providing industry-specific solutions that elevate workflow efficiency and extend durability. Discover why these valves are perfect for precision applications.

Key Benefits of Using Custom Solenoid Valves for Precision

Custom solenoid valves redefine industry standards by improving performance, durability, and regulatory compliance for precision-driven applications. The option to tailor designs for advanced solutions that address complex operational challenges is one benefit of custom solenoid valves for precision use.

Companies like Solenoid Systems excel at delivering high-quality components that meet exact specifications for industries requiring flawless performance. Our expertise encompasses a wide range of innovative solutions, like solenoid coil design, which enhances reliability in cutting-edge systems. Partnering with professionals in custom solenoid development empowers businesses to achieve unparalleled accuracy and efficiency in their operations.

Enhanced Performance

Precision engineering demands components that are capable of adapting to dynamic system requirements. Custom solenoid valves improve response times, achieving rapid adjustments in applications like automotive fuel injection systems. Enhanced flow control technology ensures accurate fuel delivery while boosting efficiency and reducing emissions.

Medical dosing systems reflect the crucial role of precision-engineered solenoid valves. Tailored configurations administer exact quantities of fluid or gas, supporting devices like infusion pumps and ventilators. These advancements mitigate risks in critical environments by providing unmatched safety and operational reliability.

Operational consistency emerges as a vital benefit of custom solenoid valves in industries facing harsh conditions. High-pressure applications or temperature fluctuations challenge generic solutions, but bespoke valves excel in maintaining consistent functionality. The customizability of solenoid solutions contributes to extended system life and reduced operational interruptions.

Material Customization

The specific operating conditions of each industry highlight the importance of material choice in solenoid valve design. Custom configurations harness corrosion-resistant metals to address environments exposed to chemicals or harsh fluids. Without specialized materials, standard components become liabilities in demanding applications.

Stainless steel solenoid valves dominate industries requiring durability and functionality in corrosive settings. For instance, chemical manufacturing plants rely on these components to handle aggressive solvents effectively. Similarly, the development of biocompatible polymers enables medical devices to meet stringent safety and compliance regulations.

Material selection also boosts cost efficiency by minimizing component wear and extending product life cycles. Customized valve materials reduce maintenance needs and enhance system reliability, especially in environments where even minor failures result in financial and operational strain.

Regulatory Compliance

Industries with strict compliance requirements depend on solenoid valves designed to meet regulatory standards. Aerospace engineering demonstrates this with custom valves providing necessary precision in complex systems. The ability to maintain complete safety and reliability under regulated conditions exemplifies their importance.

Medical devices demand unwavering adherence to FDA guidelines for patient safety. Custom solenoid valves comply with these standards, delivering precise fluid control in devices like dialysis machines and surgical tools. Tailoring the approach helps medical facilities meet the dual demands of accuracy and regulatory approval.

Regulatory testing involves navigating detailed approval processes. Custom valve designs incorporate the specifications necessary to streamline certification, speeding up deployment while eliminating compliance risks. Industries achieve precision-engineered systems that satisfy all operational and legal demands seamlessly.

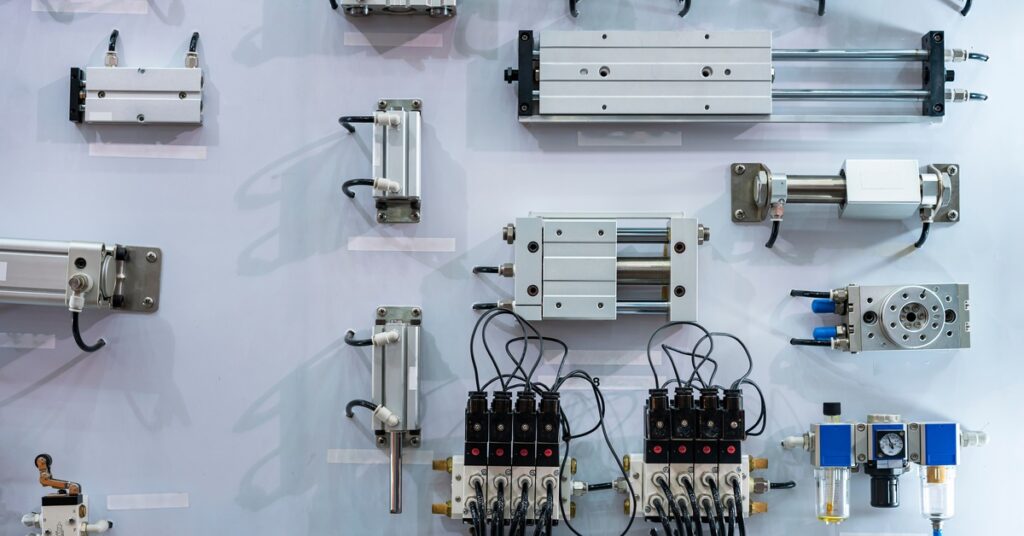

Common Precision Applications for Solenoid Valves

Industries ranging from healthcare to automotive illustrate the widespread significance of solenoid valves. Customization aligns valve performance with the specific demands of diverse sectors and meets engineering challenges head-on.

There are a range of industries that benefit from custom solenoid valves for precision use cases. Precision components are indispensable for modern technologies that need efficient, adaptable solutions.

Medical Devices and Equipment

As mentioned, medical technologies rely on precise flow regulation to safeguard patient safety and treatment efficacy. Solenoid valves are crucial in equipment like ventilators, where controlled air delivery supports life-critical functions.

Biocompatibility plays an essential role in medical device customization. Custom solenoid valves integrate specific coatings and materials that eliminate risks related to patient health or contamination. Devices like infusion pumps meet regulatory safety thresholds without compromising on operational performance.

Medical accuracy depends on valves tailored to variable conditions, such as fluid type or viscosity. Custom solenoid solutions adapt seamlessly to accommodate diverse patient needs and system configurations. Collaboration between medical professionals and solenoid manufacturers drives innovative breakthroughs in this space.

Automotive and Hybrid Vehicle Systems

Solenoid valves elevate the performance of automotive applications through precision engineering. Fuel injection systems utilize components to regulate fluid delivery and maximize engine efficiency while maintaining peak output. Reliable operation under high-speed conditions assures manufacturers of dependable functionality.

Hybrid and electric vehicle evolution highlights the versatility of solenoid valves. Advanced energy management systems require valves capable of integrating with both traditional components and innovative powertrain solutions. Custom valves offer control flexibility essential for sustainable automotive advancements.

Businesses can mitigate environmental stresses, such as extreme heat or component wear, through tailored solenoid solutions. High-temperature braking systems and suspension modules benefit from durable, adaptive valve designs. Automotive engineers rely on these innovations to establish safety benchmarks across product lines.

Aerospace and Defense Applications

Aerospace systems require solenoid valves designed to perform under extreme conditions. Fuel systems depend on precise valve functions to maintain thrust and stability in rapidly changing environments. Custom valve configurations minimize risks associated with fluctuating altitudes and temperatures.

Pressurization control in crewed spacecraft and defense aircraft is an important role solenoid components play. Preventing cabin depressurization relies on valves designed with precision to sustain safe operating conditions. Pressurization technologies safeguard both equipment and personnel in demanding applications.

Under combat conditions, solenoid valves are deployed to manage hydraulic actuators responsible for flight control surface movement. Fail-safe features integrate into control systems to maintain functionality, even after partial system damage. Shock and vibration tolerance enhancements accommodate the dynamic forces experienced during tactical maneuvers and emergency landings.

Hydraulic systems for military and aerospace operations depend on solenoid valves that withstand operational pressures. Tailored designs account for reliability under high-impact scenarios and help sustain functionality across missions.

Rely on Trusted Solutions

Custom solenoid valves support the success of industries prioritizing precision and reliability. Tailored material selection, performance optimization, and compliance alignment highlight their significant value in applications ranging from medical devices to aerospace systems.

Collaborating with professionals like the team at Solenoid Systems allows you to gain insights into innovative solutions crafted for the unique needs of precision-driven industries. Reach out today to access a suite of customizable options that empower your operations with advanced functionality and industry-compliant performance.