Virtual Solenoid Development

Virtual Development allows Solenoid Systems to develop and optimize a custom solenoid or valve solution to our customer’s requirements prior to making a physical part. This platform also allows us to study how variations in the solution affect our customer’s system and vice versa, offering a comprehensive view of potential outcomes.

The Virtual Development process saves our customer’s time and money by eliminating costly physical prototype iterations. We provide precise and reliable insights that drive informed decision-making and enhance product performance.

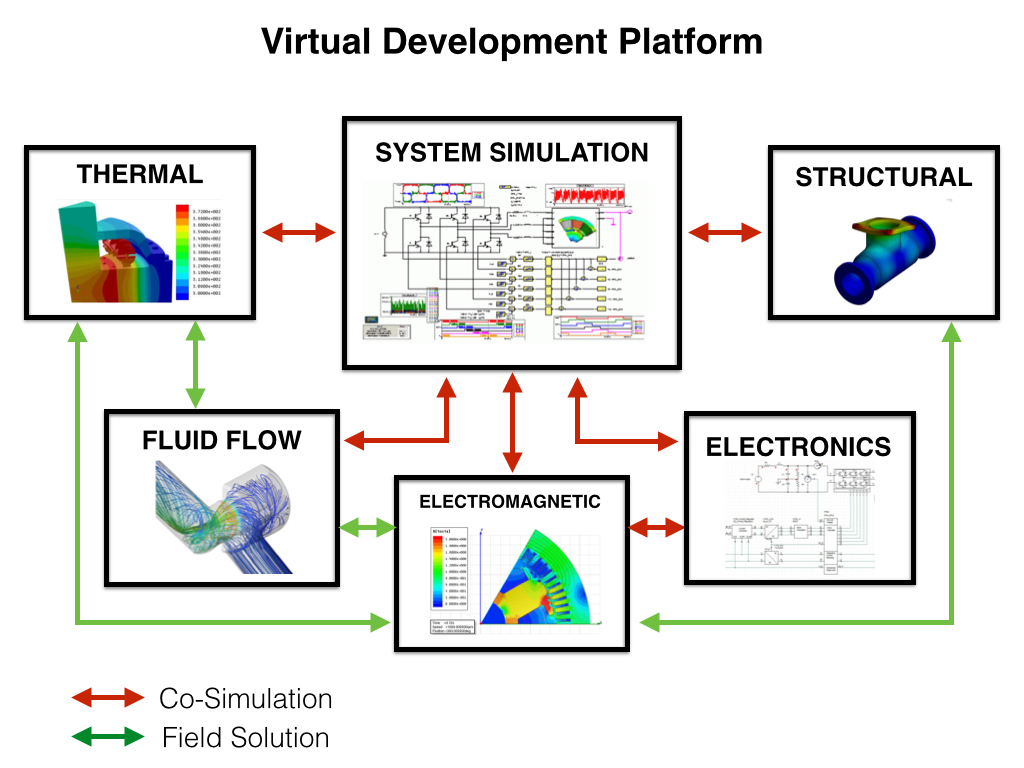

Our innovative Virtual Development Platform:

- Uses efficient and proven design workflows

- Combines co-simulation technologies, such as Electromagnetic, Electronic, Thermal and Fluid Flow

- Creates a Multi-Physics, Multi-Domain solution of devices and systems

Virtual Prototypes

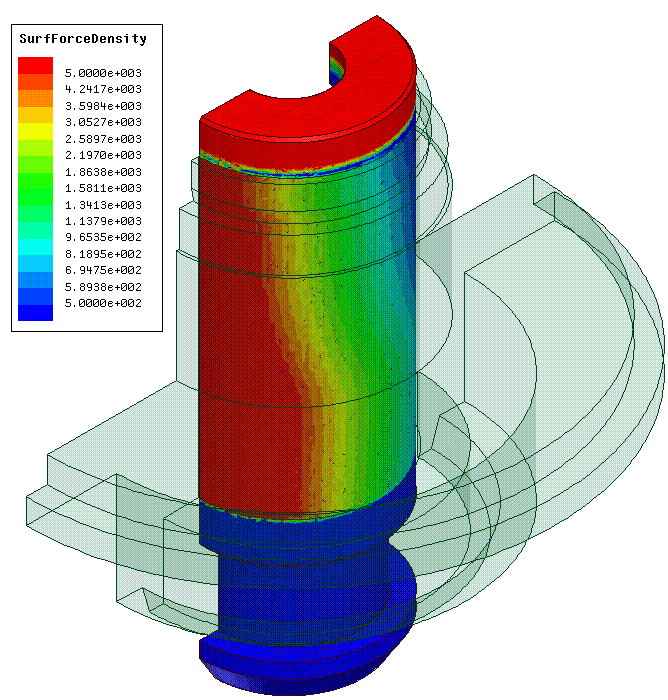

Precision virtual simulations produce a Virtual Prototype of both hardware and software. Solenoid Systems analyzes the virtual design to see how it functions in the proposed application to verify exacting performance requirements. This virtual solenoid development step validates the design’s effectiveness before we create any physical prototype. We do this to get the design right the first time, ensuring we satisfy our clients with the final product.

Our Process

We verify performance requirements by running a prototype through a series of Virtual Validation tests, such as extreme ambient temperature conditions, operational thermal cycling, vibration, EMC, and durability. By analyzing thermal, mechanical and frictional stresses in critical areas, we establish the robustness of the Virtual Design. This thorough initiative allows us to deliver efficient solutions that meet the highest industry standards.

The Benefits

Virtual Development allows us to examine and optimize rapid design variations early in the development cycle to hasten development and decrease design and development costs. By leveraging virtual solenoid prototypes, we can provide superior solutions that align with our clients’ needs and expectations.

Continuous Improvement

Our virtual solenoid development platform is continuously evolving, as we incorporate the latest simulation technologies and adhere to industry best practices. This commitment to continuous improvement enhances our processes, keeping our clients ahead of the curve.