Solenoids are essential components in countless applications, from the complex systems in aerospace and medical devices to the robust machinery in automotive and industrial sectors. These electromagnetic devices convert electrical energy into mechanical motion, performing critical functions like opening valves or activating locks. Given their importance, protecting them from environmental hazards is paramount. One highly effective protective measure is low-pressure molding, a process that significantly enhances a solenoid’s durability and performance.

This advanced encapsulation technique provides a robust barrier against moisture, dust, and vibration, safeguarding the delicate internal components. It is a key process that transforms a standard component into one capable of withstanding the most demanding operational conditions. Continue reading to explore a deeper look at low-pressure molding for solenoids.

What Is Low-Pressure Molding?

Low-pressure molding is an encapsulation process that protects electronic components by encasing them in a protective material. It uses low injection pressures, typically between 20 and 500 PSI, and relatively low temperatures. This method is ideal for delicate assemblies like solenoids, as the gentle process prevents damage to fragile wires, connections, and other sensitive parts during manufacturing. The primary goal is to create a sealed, waterproof enclosure that shields the component from external threats.

The materials used in low-pressure molding are ideal for this purpose. Polyamide hot-melt adhesives are the most common choice. These thermoplastic materials offer excellent adhesion to a variety of substrates, creating a watertight seal around the solenoid. They also possess superior resistance to chemicals, oils, and temperature fluctuations. This combination of gentle application and durable material makes low-pressure molding an excellent solution for protecting electronics without compromising their structural integrity. The result is a fully sealed and robust component.

Benefits of Low-Pressure Molding for Solenoids

Applying low-pressure molding to solenoids offers substantial advantages that directly translate to better performance and reliability. The primary benefit is protection against environmental factors. Solenoids often operate in conditions where they become exposed to moisture, dust, dirt, and corrosive chemicals. The molded polyamide acts as a complete barrier, preventing these contaminants from reaching the internal coil and electrical connections. This waterproofing is critical in automotive, marine, and outdoor industrial applications where exposure to the elements is unavoidable.

This protective layer also enhances the durability and lifespan of the solenoid. Mechanical shock and vibration can cause significant wear and tear on components, leading to premature failure. Low-pressure molding provides excellent vibration damping and structural support, securely holding all internal parts in place. By mitigating the effects of physical stress, the solenoid can operate reliably for a longer period. This increased longevity reduces maintenance costs and minimizes downtime, which is a crucial consideration for any high-stakes operation. A solenoid protected this way delivers improved performance in harsh conditions, maintaining its functional integrity where unprotected components would fail.

The Low-Pressure Molding Process

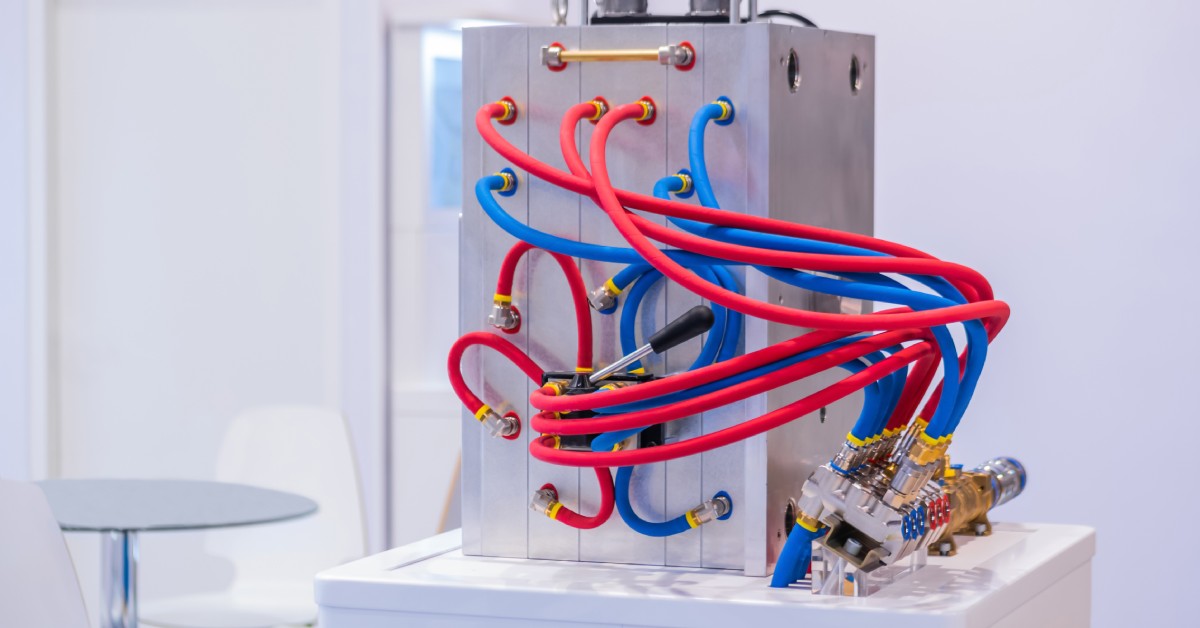

The low-pressure molding process is a precise, multi-step operation designed for efficiency and consistency. It begins with the placement of the solenoid assembly into a custom-designed aluminum mold. The mold will match the exact dimensions of the component, which allows the molding material to flow evenly around it. Once the solenoid is inside the mold cavity, the two halves of the mold are closed and clamped together.

Next, the polyamide material is heated in the molding machine until it reaches a molten, low-viscosity state. The machine then injects this liquid material into the mold at a low pressure. The material flows around the solenoid, filling every void and encapsulating the entire assembly. The low pressure is gentle enough to avoid damaging the delicate coil windings and wire terminations.

After the injection is complete, the material cools and solidifies rapidly, often within a minute. The mold opens, and the newly encapsulated solenoid comes out. The final product is a seamlessly sealed component, fully protected and ready for integration.

Solenoid Systems’ Expertise in Low-Pressure Molding

With over 30 years of experience, Solenoid Systems has honed its manufacturing processes to deliver superior custom solenoids and solenoid valves. Our expertise in low-pressure molding is a cornerstone of our commitment to quality. We utilize advanced techniques and state-of-the-art equipment to perform this critical process. Our team designs and fabricates custom aluminum molds in-house, which allows for rapid prototyping and precise control over the final product’s geometry.

Our quality control is rigorous. We monitor every stage of the low-pressure molding process, from material preparation to the final inspection of the encapsulated part. This meticulous attention to detail allows us to produce solenoids that consistently meet the highest standards of performance and reliability. As a trusted solenoid valve manufacturer, we understand that our clients depend on the durability of our components. Our extensive experience in coil overmolding and wire termination, combined with our advanced low-pressure molding capabilities, delivers robust, dependable solutions tailored to our customers’ specific needs.

Applications of Low-Pressure Molded Solenoids

The benefits of low-pressure molding make it an invaluable process for solenoids used across a wide range of industries. In the automotive sector, these solenoids are ideal for fuel injection systems, transmission controls, and anti-lock braking systems, where they become exposed to extreme temperatures, vibration, and fluids. The protective molding helps these critical components withstand the harsh under-hood environment.

In the aerospace industry, reliability is non-negotiable. Low-pressure molded solenoids are ideal in flight control systems, landing gear mechanisms, and fuel management systems. The encapsulation protects against the extreme temperature shifts and high-vibration conditions experienced during flight. For the medical field, these solenoids appear in dialysis machines, ventilators, and diagnostic equipment. Here, the sealed enclosure prevents contamination and allows for easy sterilization, a vital requirement for medical devices. Industrial applications include factory automation, hydraulic systems, and process control valves, where solenoids must endure constant use and exposure to dust and moisture.

Your Partner for Manufacturing Excellence

Low-pressure molding offers unparalleled protection for solenoids, enhancing their durability and enabling them to perform reliably in the most demanding environments. By creating a waterproof and shock-resistant enclosure, this process significantly extends the lifespan of critical components. It is an investment in quality that pays dividends through reduced maintenance and improved operational dependability.

Solenoid Systems stands as a trusted partner, offering expertise in delivering high-performance, custom-molded solenoids. Our commitment to innovation and quality has made us a leader in the field for over three decades. If your project requires robust and reliable solenoid solutions, our team can assist you. Contact us today to learn more about our low-pressure molding capabilities or to request a quote for your specific application.