Solenoid valves control vital processes in industrial plants, medical technology, military equipment, and automated production lines. As operating demands grow, small malfunctions inside a single valve can cascade into lost production time, compliance risks, or major equipment failures. For this reason, engineers and maintenance teams who recognize early warning signs can act quickly to keep entire systems performing as designed and to extend each asset’s lifespan.

In many cases, subtle changes in valve behavior—ranging from unexpected noises to irregular actuation or fluid leaks—offer the earliest clues that a problem is developing. By maintaining a schedule of proactive inspections and timely repairs, businesses build greater reliability, maintain product quality and avoid costly unplanned shutdowns.

Unusual Noises or Vibrations

Unexpected sounds from a solenoid valve often signal the beginning of internal trouble. Clicking, buzzing, or sharp rattling can point to coil fatigue, partial sticking, or loosened hardware in high-cycle environments. Overlooking unusual noises usually allows mechanical wear to accelerate, leading to bigger problems down the line.

Maintenance professionals often rely on systematic troubleshooting to find the true origin of new vibrations. Some begin by listening for the loudest source, then isolating valves one by one to check if symptoms persist. Monitoring vibration intensity across similar devices reveals patterns that distinguish ordinary wear from emerging failures.

A key sign your solenoid’s valves need maintenance or replacement is the sudden onset of new or louder vibrations in one location. Respond quickly at the first sign of trouble to reduce downtime and save on the cost of major rebuilds. Keeping incident logs and reviewing recurring symptoms leads to faster identification for future jobs.

Inconsistent Operation or Cycling

Irregular actuation or missed cycles frequently reveal underlying electrical or mechanical wear inside solenoid valves. Skilled operators watch for unusual response times or valves that open and close at unpredictable intervals. A pattern of delays or partial movement quickly points toward a failing internal component.

Process reliability suffers whenever a solenoid valve no longer matches its expected operating pattern. Sensitive manufacturing lines, cleanroom environments and high-speed sortation systems depend on precise, repeatable cycles to protect quality. Inconsistencies often trigger downstream alarms, flow errors, or regulatory compliance issues.

We at Solenoids Systems support clients who face these challenges by providing custom solenoids to optimize specific applications for businesses in need of non-standard solenoids. Engineers gain a technical edge with solutions tailored for unique demands, difficult environmental conditions, or rapid switching requirements. Through close consultation and application-driven engineering, our custom products resolve persistent cycling problems and restore dependable performance.

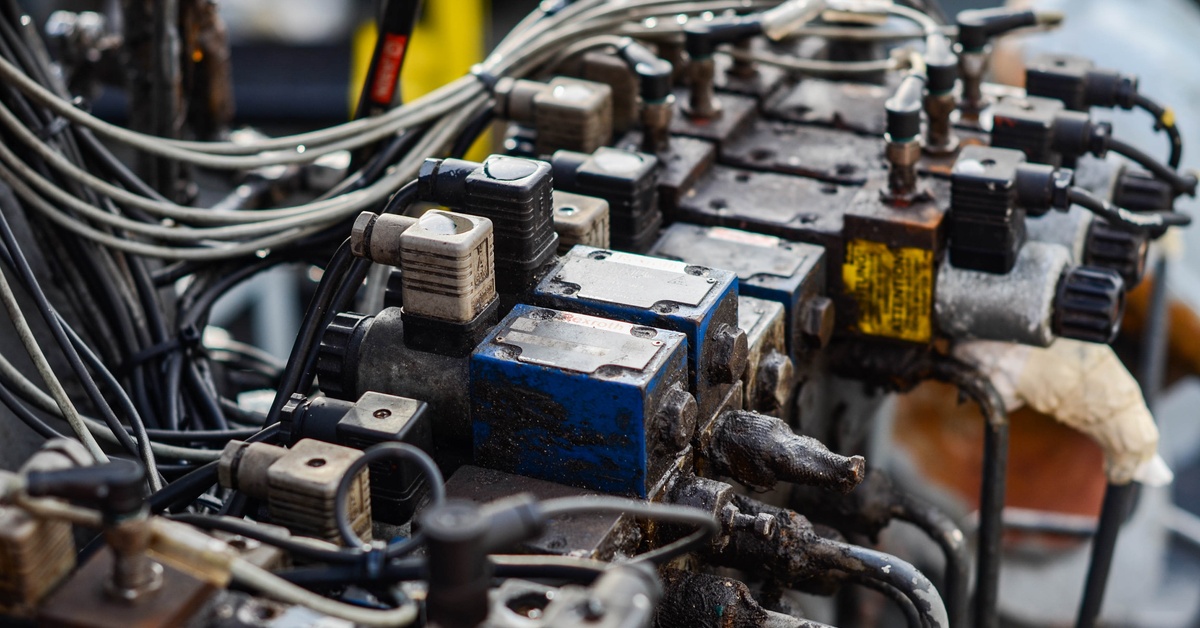

External Leaks or Corrosion

Fluid leaks from a solenoid valve can introduce contamination, reduce pressure, and compromise operational safety. Detecting a small drip or wet fitting often marks the earliest stage of seal or gasket breakdown. Technicians who act immediately minimize fluid loss, avoid costly cleanups, and prevent secondary equipment damage.

Corrosion frequently appears first around electrical connectors, metal housings, or fasteners exposed to aggressive chemicals. Surface discoloration or pitting may indicate the presence of mineral buildup or incompatible materials, which can threaten long-term system integrity. Scheduled inspections for corrosion often reveal hidden risks before visible symptoms escalate.

Teams that document findings and schedule routine checks based on application, fluid type, or operating pressure catch emerging problems ahead of schedule. Historical inspection data supports smart decision-making and justifies preventive upgrades. A proactive approach ensures that valves remain dependable, leak-free, and compliant with industry standards.

Irregular Electrical Readings or Coil Failures

Erratic electrical measurements signal coil fatigue, failing insulation, or short circuits in solenoid valves exposed to heavy workloads. High current draw, voltage spikes, or unexplained overheating can all predict eventual coil breakdown. Maintenance teams equipped with handheld multimeters or clamp meters can spot faulty readings early and isolate the affected device.

Thermal imaging and periodic amp checks add another layer of protection, especially in critical power, medical, or defense environments. Validating normal operating temperatures allows engineers to build a trend baseline for every installed valve. Sudden deviation from those trends always warrants immediate attention and component review.

One major sign your solenoid’s valves need maintenance or a replacement is finding abnormal voltage or temperature fluctuations during scheduled checks. Failing to address electrical issues risks unplanned shutdown, lost production, and system safety violations. Replacing or rebuilding coils before full failure improves reliability and reduces unplanned maintenance expenses.

Delayed Response or Actuation Lag

Sluggish or delayed actuation often points to internal sticking, worn springs, or the presence of foreign debris inside a solenoid valve. Operators may notice a gradual increase in cycle time or irregular pauses during normal operations. Subtle changes often lead to erratic throughput, missed production targets, or tighter compliance reviews.

Teams who spot actuation lag early use targeted troubleshooting, such as removing the valve for cleaning or lubrication and performing bench tests before reinstalling. Careful documentation of observed lag helps maintenance leaders identify whether the cause lies inside the valve or elsewhere in the control logic. Solutions sometimes involve recalibrating sensors or reviewing upstream controls when no mechanical fault appears.

Production lines that depend on precise timing benefit from regular valve response audits. Identifying a lagging valve before it causes defects saves time, money, and materials. Ultimately, addressing actuation delays promptly preserves system accuracy, keeps regulatory risks low and supports a strong track record for quality.

Unresponsive or Stuck Solenoids

A solenoid valve that fails to move or becomes stuck can halt operations, trigger alarms, or lead to defective output. Operators usually find stuck valves by noticing sudden process interruptions, rejected product batches, or unexpected system alerts. Fast intervention can prevent minor problems from escalating into costly downtime.

Common causes for stuck solenoids include burnt coils, mechanical wear, or obstructions created by debris or hardened deposits. Once a problem valve is isolated, maintenance teams must quickly shut down affected circuits, swap out the faulty component, and document the issue for future reference. Communication with engineering, quality, and production teams improves root-cause analysis and helps prevent repeat incidents.

Maintenance records tracking every stuck valve event provide valuable insights into system weaknesses, frequent failure points, or training needs. Reviewing information during planning cycles leads to smarter upgrades and more resilient designs. Teams that foster a culture of shared learning see the strongest gains in long-term reliability and reduced service costs.

Solenoid valves deliver performance and control at the heart of industrial, medical, military, and automotive systems. Monitor changes in sound, cycling patterns, leaks, electrical readings, and valve response times so technical teams can catch problems before they cause production loss.

Documenting and analyzing each maintenance event builds a foundation for continuous improvement and more robust designs. Long-term reliability depends on combining sharp technical skills with proactive inspections and open communication across engineering and production teams. Contact Solenoids Systems to see how our expertise with custom solenoids and industry-tailored solutions can keep your operations moving at full capacity.