Rotary solenoids support modern mechanical systems by offering precise motion control. These devices suit applications that require quick, reliable actuation. Two rotary solenoids exist: one converts linear motion into rotary motion by using a race with ball bearings. The other uses permanent magnets and has no linear motion. Let’s discuss the nuances of these different types of rotary solenoids and their applications.

Ledex Three-Ball Race Rotary Solenoid

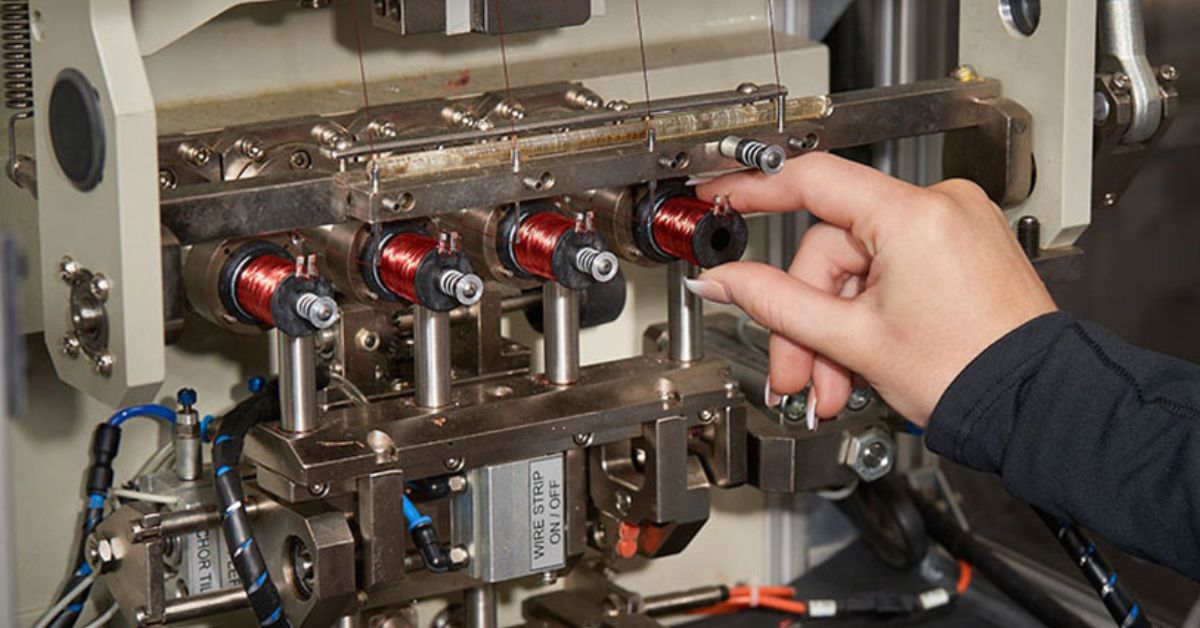

The Ledex three-ball race rotary solenoid introduces rotational motion in a compact, energy-efficient form. It has three inclined ball races arranged in a helix to convert linear motion into rotary motion.

This unique design ensures smooth, reliable operation, making it particularly useful in precision-demanding environments such as automated assembly lines. These solenoids excel in controlling robotic arms for precise component placement and handling.

Key advantages of the Ledex rotary solenoid include an impressive service life ranging from 1 to 5 million cycles, potentially reaching up to 50 million cycles using long-life components. It delivers more torque than other solenoids, while also offering exceptional resistance to shock and vibration. Moreover, its functionality extends across extreme temperatures from -55°C to 130°C.

Ledex Ultimag Rotary Solenoid

The Ledex Ultimag improves permanent magnet rotary solenoids by delivering high-speed rotary motion without relying on linear conversion. Ideal for applications requiring rapid actuation, such as camera shutters and optical devices, the Ultimag prioritizes speed and reliability.

With its high-energy permanent magnet, the Ultimag achieves faster speeds than traditional solenoids. The solenoid’s unique bidirectional, center-return function allows it to operate efficiently in open- and closed-loop systems.

The Ultimag ensures a long service life, capable of enduring up to 100 million cycles. Its compact, straightforward construction allows for swift response times and minimal maintenance, making it perfect for high-speed environments.

Applications Across Industries

The applications for different types of rotary solenoids highlight their versatility. Their varied designs allow solenoid valve manufacturers to choose the right type for specific industrial needs.

In particular, the Ledex Three-Ball Race supports precision in door and safety interlocks, enhancing security systems. It also controls product release in vending machines and moves items accurately in warehouse automation, boosting efficiency.

The Ledex Ultimag Rotary Solenoid excels in high-speed tasks. It sorts and scans logistics quickly, ensuring fast parcel handling. In money management, it handles cash swiftly for accurate transactions. It also regulates fluid flow in rotary proportional valves.

Choosing the Right Rotary Solenoid

Selecting the appropriate rotary solenoid hinges on understanding the specific demands of your application. The Ledex Three-Ball Race Rotary Solenoid excels in scenarios requiring robust performance, such as door/safety interlocks and medical diagnostic equipment.

In contrast, the Ledex Ultimag Rotary Solenoid offers high-speed capabilities and bidirectional flexibility, so it’s ideal for high-speed sortation and industrial applications. When choosing between these options, consider whether the priority lies in durability or rapid and precise actuation.