Solenoid valves are essential components in various industries, from aerospace to food and beverage. While standard valves serve many applications well, custom solenoid valves can offer significant advantages. Review the benefits of custom solenoid valves over standard ones for deeper insight.

Tailored Design for Unique System Requirements

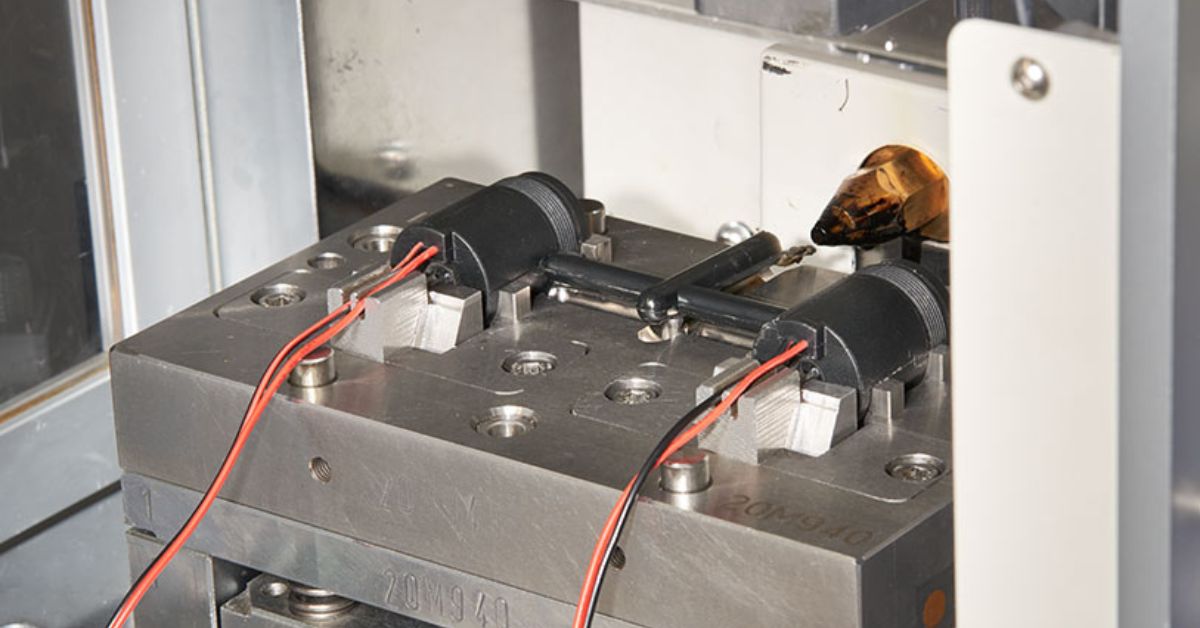

Custom solenoid valves excel in applications where specific system requirements are paramount. Unlike standard valves, which follow a one-size-fits-all approach, custom valves fit the unique needs of your system.

This tailored design enhances overall efficiency and ensures seamless integration with existing components. Engineers can work closely with solenoid manufacturers to specify dimensions, materials, and functionalities, resulting in a valve that performs optimally within its environment.

Improved Performance and Reliability

Custom solenoids offer superior performance compared to their standard counterparts. These valves can reduce the likelihood of malfunctions and maintenance issues by addressing specific operational demands and conditions.

This, in turn, leads to increased uptime and longevity of the system. For industries such as aerospace and defense, where precision control in critical systems is essential, the enhanced reliability of custom valves is invaluable.

Flexibility To Match Specific Environmental Conditions

Another benefit of custom solenoid valves over standard ones is their environmental flexibility.Custom valves can withstand specific environmental challenges, such as extreme temperatures, corrosive substances, or high-pressure conditions.

This flexibility makes them an ideal choice for industries like energy, where they control various liquids and gases in complex systems. In the food and beverage industry, custom valves ensure sanitary and specialized fluid handling, meeting stringent regulatory standards.

Cost Effectiveness in the Long Run

Custom solenoid valves may come with a higher initial price tag, but they’re more cost effective than standard ones in the long run. Their improved efficiency and reduced downtime translate to significant savings over time.

For instance, manufacturing plants that rely on automation and process control benefit from the decreased need for maintenance and replacement parts, leading to substantial cost reductions. Investing in custom valves upfront pays dividends in operational efficiency and overall cost savings.

Enhanced Safety Features for Critical Applications

Manufacturers can build solenoids with additional safety features for critical applications. For example, custom valves ensure precise fluid control in healthcare equipment and reliable operation in water treatment systems. These enhancements protect the system and its components, ensuring the safety of personnel and the environment.