Industrial businesses prioritize energy efficiency to reduce operational costs and environmental impacts. Solenoid design offers significant gains in this area. Solenoid valves, integral components in various systems, control the flow of liquids and gases. Optimizing their design leads to substantial energy savings. Review these practical ways to design energy-efficient solenoid valves for more information.

Use High-Efficiency Coils

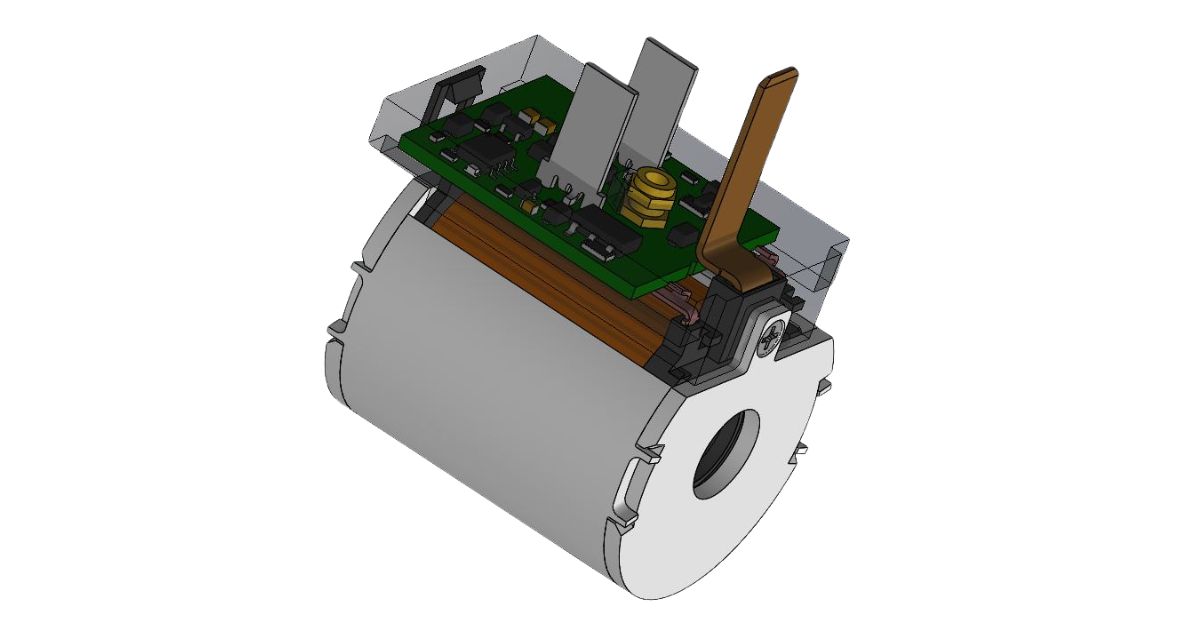

The solenoid coil is the heart of the valve and affects energy consumption. Opt for high-efficiency coils that require less power to operate. These coils generate the necessary magnetic force with lower electrical input to reduce the overall energy usage. In addition, advanced coil designs can offer faster response times and improved reliability.

Optimize Material Selection

Choosing the right materials for your solenoid valve components can impact both performance and energy efficiency. Materials with low friction and high wear resistance, such as polymers or stainless steel, can reduce the energy required to actuate the valve. Additionally, using materials that provide excellent thermal conductivity can dissipate heat more effectively and enhance the valve’s efficiency.

Implement Smart Control Systems

Design energy-efficient solenoid valves with smart control systems to adjust the operation of the valve based on real-time data. These systems can optimize the valve’s opening and closing cycles while reducing unnecessary energy consumption. For instance, integrating sensors to monitor flow rates and pressure can facilitate precise control, ensuring the valve operates only when needed.

Minimize Pressure Drop

Designing solenoid valves to minimize pressure drops is crucial for energy efficiency. A high-pressure drop across the valve requires more energy to maintain the desired flow rate. Streamlining the internal pathways and ensuring smooth transitions between different sections of the valve can minimize pressure drop. Additionally, computational fluid dynamics (CFD) simulations can optimize these designs.

Utilize Energy-Efficient Actuation

Consider using energy-efficient actuation methods, such as pulse-width modulation (PWM). This technique involves rapidly switching the solenoid coil on and off, maintaining the necessary magnetic force with lower average power consumption. PWM can reduce the energy required to keep the valve in a particular state, which is especially valuable in applications where the valve remains actuated for extended periods.

Focus on Maintenance and Upkeep

Over time, wear and tear can increase friction and reduce the effectiveness of the valve components. A proactive maintenance schedule can help you identify potential issues before they escalate, ensuring the valve continues operating efficiently. Cleaning and lubricating moving parts can also reduce energy consumption by minimizing resistance.

Why Choose Solenoid Systems?

Partnering with an expert can help business leaders implement these strategies. Solenoid Systems specializes in solenoid valve design and manufacturing to meet industry needs. With cutting-edge technology and innovative solutions, we guarantee that your valves will contribute to your energy-saving goals.