Selecting the right solenoid for your application is important. You must consider multiple factors to ensure optimal performance, durability, and efficiency. Here are six tips for choosing the right type of solenoid for your projects.

Understand Your Application Requirements

Are you looking for a holding solenoid, a push solenoid, or a pull solenoid? Each type has unique characteristics that are ideal for different tasks. Holding solenoids maintain a position, whereas push and pull solenoids initiate movement more effectively.

Clearly defining your needs will streamline your selection process and ensure you choose the most suitable solenoid for your application. This proactive approach will save time and enhance your system’s efficiency and performance.

Consider Environmental Factors

Temperature, humidity, and overall operating conditions can influence the solenoid’s performance and durability. For instance, you must select a solenoid that can withstand certain conditions without compromising its functionality if your application involves extreme temperatures or high humidity levels. Doing so ensures that the solenoid remains reliable and effective even under adverse conditions.

Evaluate Power Requirements and System Compatibility

Assess your solenoid’s power requirements to ensure it is compatible with your existing system. Key considerations include:

- Ensuring the solenoid matches your system’s voltage and current specifications.

- Opting for solenoids with efficient power consumption to avoid excessive energy use and heat generation.

- Evaluating the solenoid’s response time to ensure it meets the operational speed required for your application.

Look for Customizable Features

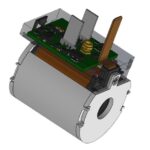

Sometimes, off-the-shelf solenoids may not meet all your project needs. Looking for ones with customizable features is a smart tip for choosing the right type of solenoid. Customizable solenoids can provide the flexibility needed for unique project requirements, whether it’s adjusting the stroke length, adding sensors, or modifying the mounting configuration.

Factor in Space Constraints and Mounting Options

Often, people overlook space constraints and mounting options, but these factors are essential for seamless integration. Measure the available space and determine how you will mount the solenoid. Some solenoids fit compact spaces, while others require more room. Ensuring that the solenoid fits well within your design prevents installation issues later on.

Compare Cost and Long-term Maintenance Needs

Lastly, you should compare the solenoids’ cost and long-term maintenance needs. While the upfront cost is a factor, consider the total cost of ownership. A cheaper solenoid might initially save money but could incur higher maintenance costs. Investing in a higher-quality, durable solenoid is more cost-effective in the long run.

Final Thoughts

Selecting the right solenoid involves a comprehensive evaluation of your application needs, environmental conditions, power requirements, and other essential factors. By following these tips, you can ensure you choose solenoids that deliver optimal performance and value.

Consider Solenoid Systems for top-quality solenoids and expert guidance. With years of experience as solenoid manufacturers, we provide high-performance solutions tailored to your needs. Get in touch with us today!